Free Shipping

1970 Truck Camper Plans

Build a Vintage Wood Frame Cabover Pickup Camper

|

1970 Truck Camper Plans

Build a Vintage Wood Frame Cabover Pickup Camper

|

PDF Format |

|

|

All Orders Processed

On a Secure Server

|

Price $12.95

|

|

Get a restored copy of these Vintage 1970 Truck Camper

Plans with 11 Pages of Enhanced and Enlarged Figures and Illustrations

and Searchable Text.

|

We will email these plans, to the address provided

with your payment, within 48 hours following receipt of your order.

|

|

|More

Vintage Trailer Plans|

|

|

|

|

|

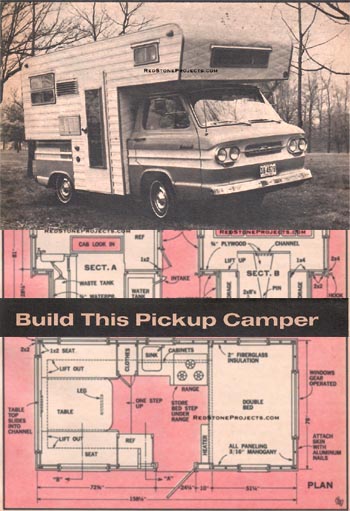

| IF YOU can't buy it, build it. This was my decision

when I couldn't find a camper body that would meet my particular needs

and pickup. If you have a similar problem, you might do as I did and follow

this procedure to suit your own pickup. Though the dimensions of your truck

will be different, the method is relatively universal.

My first step was to visit dealers in stock campers to

decide on the equipment I could use. Next, I measured and laid out on paper

the dimensions of the pickup box. My truck is a Corvair 95 Rampside (since

discontinued) which made possible an interesting side entrance door. Your

pickup no doubt will require a rear entry but the general building approach

is the same, no matter the pickup. I drew a set of plans for building the

camper with a scale of 1/8 in. to the foot. I decided on this scale because

it would best show the details of framing members - vertical and horizontal

stringers - that make up the wall and roof sections. The drawings showed

windows and door locations and the best placement of such interior appointments

as stove and refrigerator, kitchen and dining areas. At the outset, I wanted

to cut the weight of the camper and so I carefully selected appointments,

appliances and construction materials to keep the finished weight of the

camper as low as possible.

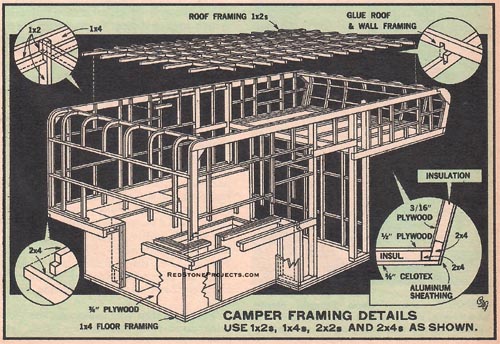

I selected redwood for the framing material of

the sides and top. On the floor and forward portion of the camper I used

3/4-in. fir plywood because of its strength and rigidity. I assembled the

floor sections to the front wall of the camper, also using 3/4-in. plywood.

This involved tailor-fitting the various cuts to the exact area size of

the pickup box. |

|

|

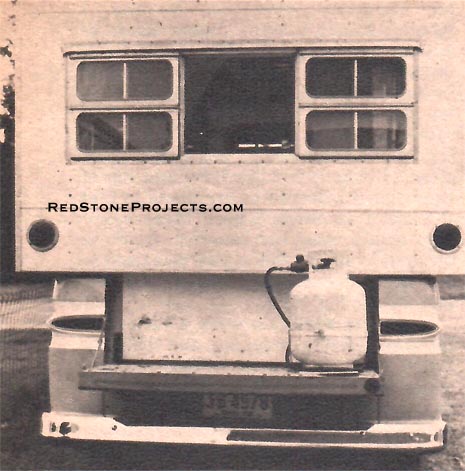

CAMPER rear view showing position of propane

tank on tailgate to comply with laws. Windows are fitted with screens.

|

| After completing the floor assembly, I turned to the

sides next. For this I selected l x 8 x 10-in. redwood boards. I had these

boards milled to an exact 3/4-in. thickness at a lumber mill. This was

an important operation because I wanted to use a 3/4-in. router blade to

cut the half-lap joints. Therefore, it was imperative that the material

thickness be an exact 3/4 in. to assure a tight-fitting lap joint. These

boards then were rip-sawed to 1 1/2 in. width on a table saw for use as

the vertical studs and horizontal stringers for the sides and top of the

body. I referred to my plans to find the exact locations where these members

would cross one another. At these marked locations the router was used

to cut 3/4 x 3/4-in. rabbets. This made a perfect fitting lap joint.

Next, the verticals were attached to the assembled

floor section and the horizontal stringers were glued and clamped to the

verticals. At points where I believed there would be stress, I further

secured the lap joints with a counter-sunk 1 1/2-in. flathead wood screw.

Consideration and attention were given to the location of windows and doors

when fabricating these side members so lap joints would not fall in a position

that might interfere with the installation of the windows, doors and vents. |

|

|

|

WATER STORAGE tanks are filled from outside

the camper. Fittings for the camper were purchased from a local mobile

home dealer.

|

| This type of construction results in a honeycomb or cellular

configuration which makes it easy to place the 1 1/2-in. fiberglass insulation

in each of the cells. The top of the camper was assembled in exactly the

same manner as the sides and the two were attached. The front and rear

of the top were rounded where they met the front and back. |

|

|

Figure 1. Truck Camper Framing Details

|

| The superstructure of the camper now was complete

and ready for the interior plywood. The interior was paneled with 1/4-in.

mahogany panel board. This was secured to the interior skeleton with contact

cement applied between the stringers and the back face of the panels. In

areas where I thought there would be greater stress, I fastened the panels

to the frame with 3/4-in. flathead brass screws countersunk into the panels.

After the paneling was in place I set all the windows and the door. I finished

these off with aluminum moldings. |

|

|

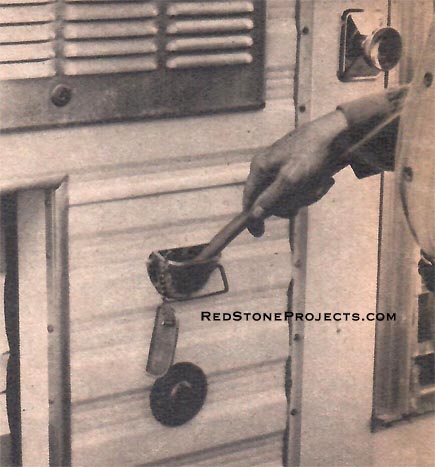

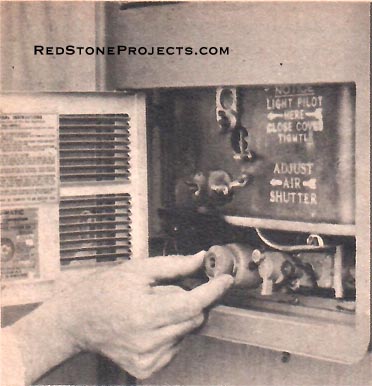

HEATER is a compact model which provides

comfort in subzero weather. It vents behind the truck cab protected from

the weather.

|

| The next step was to lay out the electrical circuits

for the interior lights, taillights, stop and clearance lights. At the

same time, I installed the wiring cable for the intercom system for communication

between body and truck cab. After the wiring, I installed the fiberglass

insulation in the cells formed by the stringers. The fiberglass is best

cut to size with a sharp knife. Any other means of cutting and handling

this material can be hazardous. (Broken glass fibers can penetrate the

skin and cause irritation.) With the insulation in place, the following

step was to install the exterior aluminum skin to finish the body.

The aluminum covering which I used for the camper

was the regular grade and weight of prefinished white trailer siding. This

was provided in exact lengths and widths to meet my specifications. |

|

|

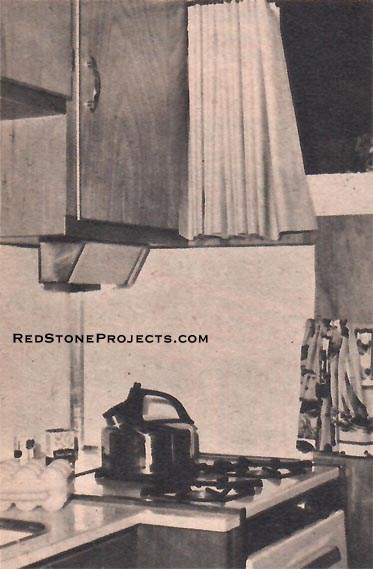

CABINETS above range provide plenty of

storage. Every inch of interior space is utilized for efficient living

and most comfort.

|

| The aluminum was fastened to the skeleton framework with

3/4-in. hex-head aluminum screws. After the skin on the sides and top there

remained only the roof rail, outside window garnish and drip caps for the

windows and door.

This is a good place to mention the source for the appliances

and building materials that were used in this project. An excellent supplier

can be found at practically any mobile-home sales and service center. Most

of these are affiliated with some large trailer supply dealer. Throughout

the planning and building of this custom camper an attempt was made to

keep everything light as possible but at the same time functional. |

|

Figure

2. 1970 truck camper plan and elevation views with dimensions.

|

Get a restored copy of these Vintage 1970 Truck Camper

Plans with 11 Pages of Enhanced and Enlarged Figures and Illustrations

and Searchable Text.

All Orders Processed

On a Secure Server

|

|

| Modern appliances and materials that would require minimum

maintenance were chosen. These appliances can be repaired by most mobile

home dealers and parts are readily available.

With the interior of the camper coach completed there

remained only the placement and fastening of the gas stove, refrigerator,

space heater and kitchen sink. The cabinet doors and drawers were made

of 3/4-in. birch plywood sanded and varnished to match the interior paneling.

The floor was covered with 9-in. square vinyl tile, except for the dinette

area, which was covered with nylon carpeting. |

|

|

HOMESTYLE conveniences are to be found

throughout this handsome Camper. All appliances operate on both 12 and

117 volts.

|

| The cost of all materials, including appliances, was

about $850 and the project required about 200 spare-time hours in building.

The resulting camper fitted perfectly into the pickup box. The completed

weight of the coach is 1,030 lbs., well within the weight limit I had estimated

and set.

In use this camper has turned out to be a good performer.

It handles well and the weight is evenly distributed for cornering and

roadability. When the pickup must be used without the camper, a sling can

be attached to four eyebolts at the corners of the camper and the whole

thing can be hoisted out.

For living in, she lives up to our expectations also.

There is plenty of storage space, the body is cool in summer and warm in

chill nights. Interior appointments are both functional and comfortable

with all conveniences. |

|

|

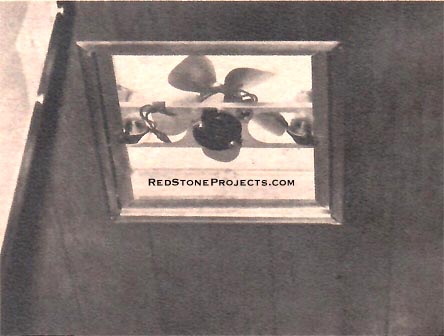

VENTILATOR FAN is motor-driven and placed

to exhaust interior air most efficiently. The fan has approved weatherproof

wiring.

|

| I was proud of the finished job and had lived up to my

promise that if I couldn't buy it, I'd build it. |

Any 2 Vintage Trailer Plans

$19.95 FREE Shipping |

|

Select 2 Vintage Travel Trailer Plans

|

|

|