Free Shipping on All U.S. Orders

All Orders Processed on a Secure Server

Build This Streamline Family Vacation Trailer

Detailed Vintage Camping Trailer Plans

|

15 Foot Family Vacation Trailer Plans

DIY Vintage Camping Trailer Build

|

PDF Format |

|

|

All Orders Processed

On a Secure Server

|

Price $12.95

|

|

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

|

We will email these plans, to the address provided

with your payment, within 48 hours following receipt of your order.

|

|

|More

Vintage Trailer Plans|

|

|

|

|

|

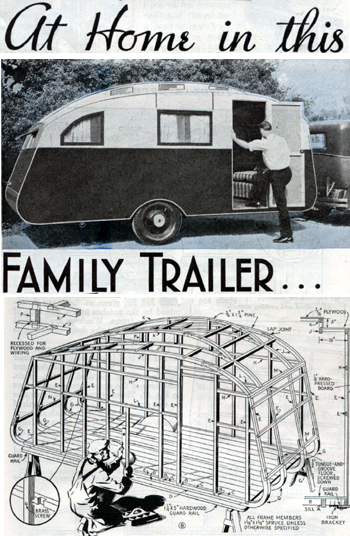

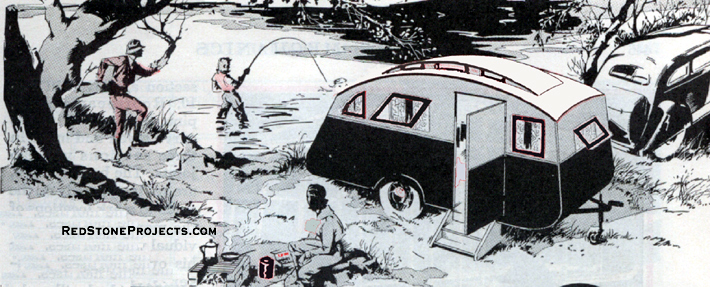

Every Need for Touring Is Met in This Trailer;

Cookstove, Sink, Icebox, Clothes Closet and Other Equipment Are Conveniently

Arranged and Adequate Cross Ventilation Is Provided by Numerous Screened

Windows.

|

|

PART 1: BUILDING THE CHASSIS

STYLED in the latest streamline, roomy, yet light and

sturdy, this trailer affords you all the comforts of home. "Roadability"

is assured by a clever arrangement of interior fittings to give an equal

distribution of weight. An underslung axle of unique and original design

maintains a low center of gravity and at the same time provides a spring

seat as close to the wheel as possible. The tubular construction of the

axle reduces the unsprung weight to the minimum.

Construction begins with the sills. Fig. 1 gives you a

perspective view of the under-frame assembled, and over in Figs. 4 and

5 you will find the essential dimensions. The sills, A in Fig. 1, are of

selected hard maple, 2 1/4 by 4 in. in cross section, and are joined by

spruce cross members, B, 1 1/2 by 2 1/2 in. in section. All joints are

mortised and secured with 3/16-in. carriage bolts. |

|

|

| Before you begin work, notice from Fig. 4 that all the

cross members, except the ends, are spaced on centers. A section of each

sill between the third and fifth cross members is rabbeted to take the

fender as shown in Fig. 1 and the detail at the left in Fig. 5. With this

rabbet cut at the bench you can mortise the sills and cross members.

The care you use in mortising determines to a great extent

the rigidity and strength of the frame. Accuracy in laying out the spacing

and depth of the cuts and the use of a miter box in sawing down the shoulders

of the mortises will assure a close fit. Scoring the depth of each mortise

with a marking gauge will aid in chipping out the waste with a chisel,

as the last few chips will break off at the scored line. Now you level

two sawhorses on the floor and place the sills on these. Then with the

cross members in place you can check the fit of all the joints and bore

the 5/16-in. holes for the bolts. When you bore these holes, it will help

to clamp the parts tightly together so that the bit goes through the two

members as though they were one piece. |

|

|

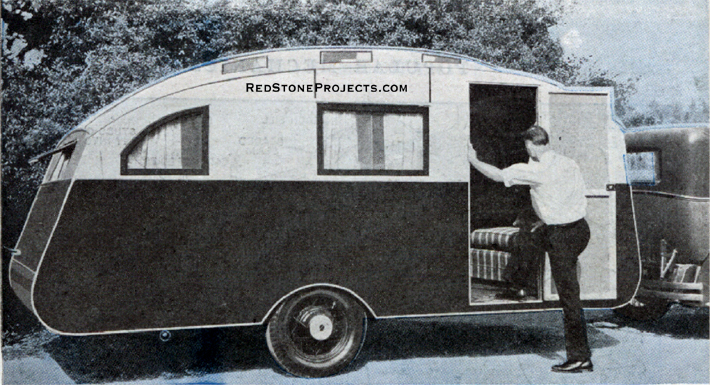

DIY Family Vacation Trailer Floor Plan

|

| Waterproof casein glue is used in all joints of the underframe.

Now with this assembly set up and bolted together, be sure, before the

glue sets, to check the frame at each corner with a square. If necessary,

put clamps on the frame to hold it in the square position until the glue

is dry. |

|

|

For Sleeping Quarters That Will Accommodate Four

Persons, a Luxurious Studio Couch Is Placed at Each End; the Aluminum-Painted

Top Reflects Heat, Keeping the Interior Cool; for Added Insulation, the

Walls and Top May Be Made Double.

|

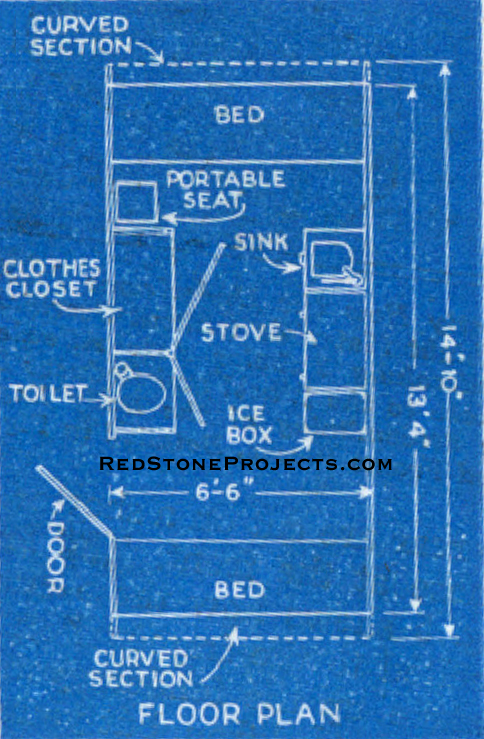

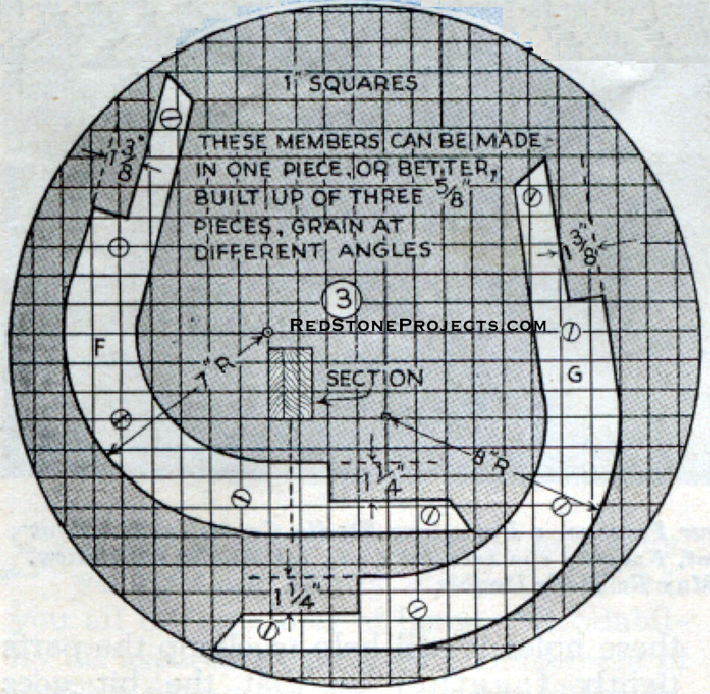

| Now you're ready for the lower rails, fenders, springs,

and the curved end members. The cross members are halved at, the ends to

take the lower hardwood rails, which are 1 1/4 by 1 1/4 in. in section.

These rails, part D in Fig. 1, are bolted to the cross members with bolts.

There are two longitudinal pieces halved into the cross members directly

over the axle. These form an opening for the water tank. Fig. 3 shows what

you will want to know about the curved end members, F and G. |

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

|

Figures 1 and 2.

This Shows Exactly Now the Underframe Is Assembled,

Using Light Materials without Sacrificing Rigidity; an Underslung Tubular

Axle Affords a Spring Mount Close to the Wheel and Reduces Unsprung Weight;

Streamlining of the Body Begins with the Curved Frame Pieces, Detailed

in Fig. 3.

|

|

| Those at the rear are cut on a shorter radius than those

at the front. The lower detail in Fig. 5 shows how these curved pieces

are bolted to the frame. You can, of course, make up the fenders yourself

from heavy galvanized iron, but your tinsmith, with the equipment he will

have at hand, can do a neater job in far less time and at a nominal cost.

The fenders are cut on a 16-in. radius but not to a full semicircle, as

they are only 14 in. deep and 10 in. wide. Chevrolet front springs are

mounted on the sills as in Fig. 1, the shackle brackets being bolted to

the sill as in the detail at the right. The bolts holding the shackle brackets

should be a snug fit in the holes bored through the wood. It's a good idea

to use lock washers on all bolts in the underframe.

Now that you've progressed to this stage, you're ready

to start with the axle. As shown in Fig. 2, this is a simple affair consisting

of two wheel-spindle brackets of electric steel joined with a chrome-molybdenum

tube. You can buy the tube but it will probably be necessary to make the

spindle brackets. The additional cost of this work will be money well spent,

as this type of axle is so far superior to anything that can be improvised

from standard auto parts. After you get your axle made up as suggested

in Fig. 2, you make a trial fit on the springs, but do not attach the axle

permanently to the frame as the latter must remain on the sawhorses until

the upper structure is set up. |

|

|

Figure 3. Curved Frame Pieces Streamline the Trailer

Body.

|

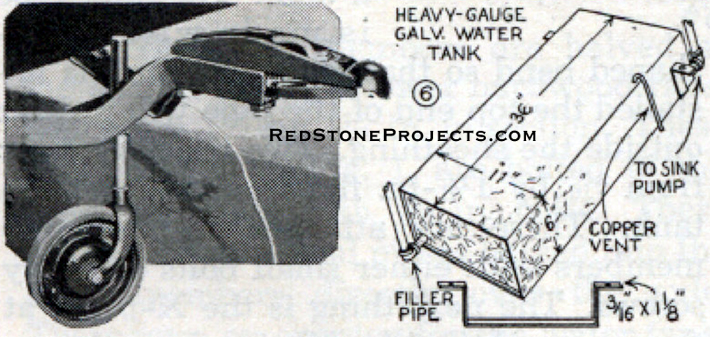

| Two jobs remain to be done before you have the underframe

complete. The first is making and installing the 14-gal. water tank, which

is dimensioned in Fig. 6 and shown in position in Fig. 4. Once again, a

tinsmith can save you a lot of time and bother in building such a tank.

The filler pipe is made with an S-shaped bend so that when the tank is

installed the top end of the pipe will project outside the sheathing. Two

brackets, bent from 3/16 by 1 1/8-in. flat iron, support the tank. These

are attached to the cross members with either small bolts or heavy screws.

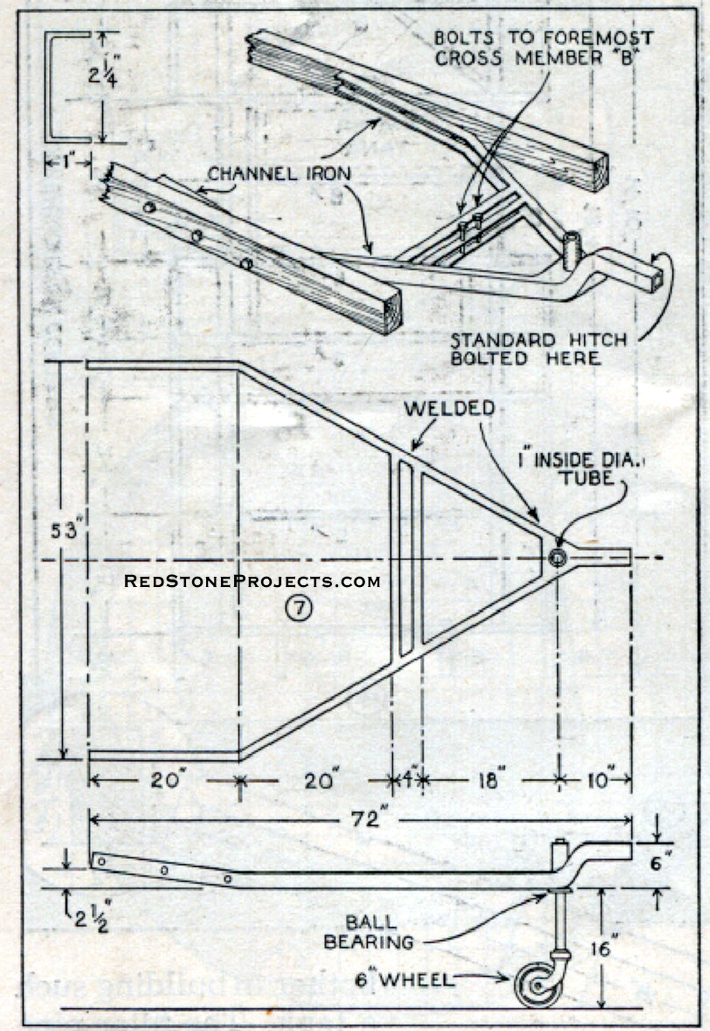

The next thing is the X-brace at the rear, and the 1 by 2 1/4-in. channel-iron

A-frame, which carries the coupler and the caster wheel at the front. Details

on the construction of the A-frame are given in Fig. 7, and the X-brace

is shown installed in Figs. 1 and 4. The A-frame calls for a simple welding

job and the fitting of a bushing to take the spindle of the caster wheel.

The bushing can be made from a short length of tubing. The A-frame is not

installed permanently at this time as it would interfere with the body

sheathing.

You will need two folding jacks to support the rear end

of the trailer when it is parked. These are attached to the sills with

a bracket as in Fig. 1; they serve to prevent tipping and ease the weight

resting on the tires. Provide a reliable catch or hook so that the jacks

will not drop down when you're on the road. You can also get out the filler

pieces, C in Fig. 1. |

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

|

Figure 4.

Fig. 4 Gives You a Dimensioned Plan of the Underframe

Shown Assembled in Fig. 1.

|

|

| The position of these is shown in the enlarged detail

at the left. These pieces are cut to fit but are not installed permanently

until the studs, E, are erected. In connection with the fitting of these

pieces, see the lower detail in Fig. 5, which shows the curved end member,

G, bolted both to the cross member and the filler piece, C. This assembly

is not completed until the studs are glued and screwed to the cross members

before the filler piece is put in place. |

| When you cut these filler pieces be sure of the length.

Properly cut and fitted, with the studs in place, they contribute greatly

to the strength and rigidity of the whole structure. |

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

|

|

Figure 5. Details of the Sills and Lower Rails.

|

|

| Just now is also a good time to check the frame over

for slight inequalities which might cause trouble when laying the floor.

A straightedge will show up any high spots on the cross members. If necessary,

level up with a plane. |

| To ensure close fit of the studs, scrape away any excess

glue where the cross members join the outer rails. For wheels you can use

any of the standard wire auto wheels fitted with a 5:50 by 17-in. tire.

Suitable bearings should be purchased to fit the wheel spindles. |

|

|

Figure 6. Galvanized Tank Supplies Water to a

Marine-Type Pump.

|

| Now to finish up, you can give all the parts of the underframe

two coats of black paint, a primer first, then follow with a body coat.

It is well, in painting, not to cover those sections of the lower rail

where the studs join the rail and the end of the cross member, as glue

is to be used in these joints. |

|

|

Figure 7. An A-Shaped Frame of Channel iron Carries

the Trailer Hitch and Caster Wheel.

|

|

|

|

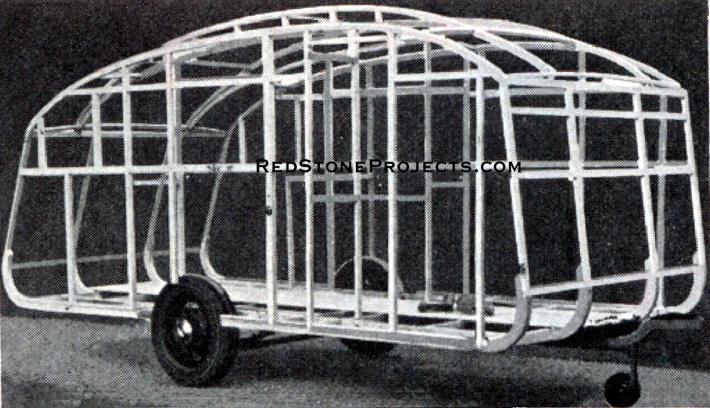

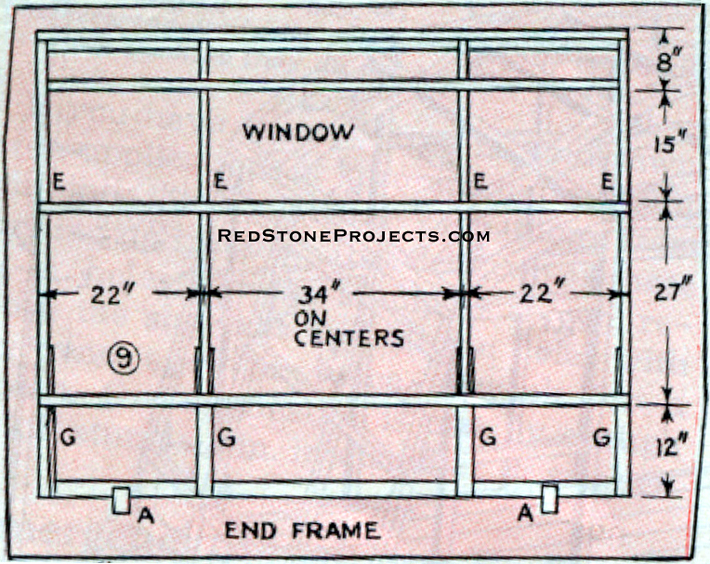

PART 2: BUILDING THE TRAILER FRAME

NOW that you have completed the trailer chassis, Fig.

8 shows what's next. Notice first, from Figs. 11 and 14, that the position

of the vertical and horizontal members differs on the two sides of the

frame. The end frames, Fig. 9, are identical with exception of the top

cross member, which is 1 in. lower on the rear frame. To start the framing,

set up the corner studs, E in Fig. 8, then follow with the top rails, H,

and those across the ends, M, which are double. At the lower ends the studs

are halved and screwed to the cross members, B. Then the filler blocks,

C in Fig. 8, are screwed to the lower rail, D, to complete the joint. All

joints in the entire frame are set in waterproof casein glue and wherever

vertical and horizontal members join, the two parts are halved to make

a flush joint which is held, with a 1-in. screw. Some care is necessary

in mortising, as a tight joint adds greatly to the strength of the structure. |

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

|

Figure 8.

Trailer Body Framing Details

|

|

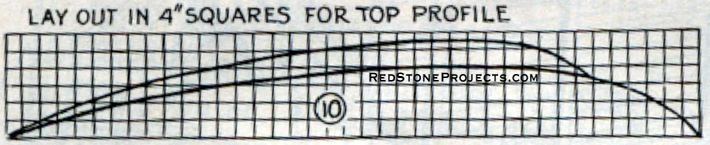

| Profiles of the roof and raised center section are given

in Fig. 10. Roof beams are of pine, band-sawed to the curve given and made

in three sections with lap joints. The beams, Fig. 8, are set temporarily

on the studs to mark locations of the mortises. Each individual will probably

have his own method of assembly, and whichever method achieves the purpose

with the least complication, should, of course, be chosen. Note, from Fig.

11, that dimensions between the studs are not given as these are determined

by the notches in the side rails of the chassis frame. Windows are identical

on both sides, but the door, of course, is only on the right side. |

|

|

Provision is made in the framing for building

in a sink and a compartment for a gas stove, also storage cabinets for

clothing, food and cooking utensils.

|

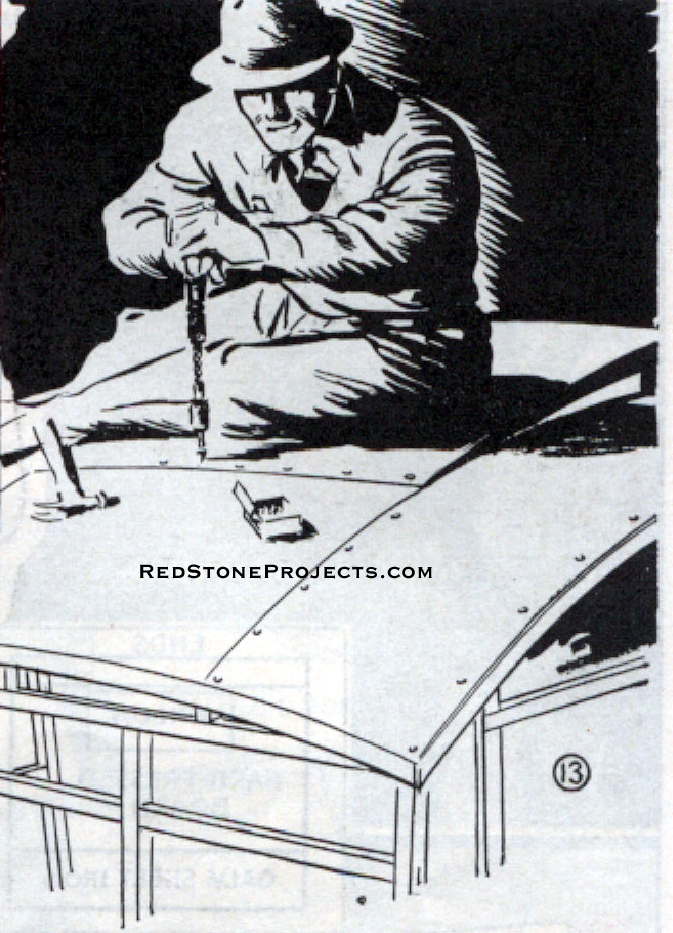

| The framing for the raised center section of the roof

is erected upon the inner beams, J in Fig. 8, and cross members are installed,

being mortised at the joints. Locations of the cross members are given

in Fig. 12. These pieces are the same size as the studs and rails, and

are mortised into the curved members of both roof and raised center section.

In order to leave space for the plywood roof, Fig. 13, on top of the curved

inner members, J, the short studs or uprights, P, Fig. 8, are notched at

the bottom. This construction assures a rain-tight joint. |

|

|

Figure 9. Trailer End Frames

|

| A cross section of the completed body is given in Fig.

8. This also illustrates the installation of a hardwood guardrail along

the bottom, secured to cross members with bolts and angle brackets. This

guard will prevent possible damage to the side of the trailer in parking

lots and on the highway. An automobile bumper, attached to the sills by

means of extension bars, will be a wise precaution for protecting the rear

of the trailer. |

|

|

Figure 10. Trailer Top Profile Layout and Dimensions

|

| When the upper structure is all complete, the floor can

be laid. This is 1/2-in. pine, tongued and grooved. Screws are used to

fasten it in place. In this way it will add greatly to the rigidity of

the structure. This done, the entire frame is given a priming coat of paint.

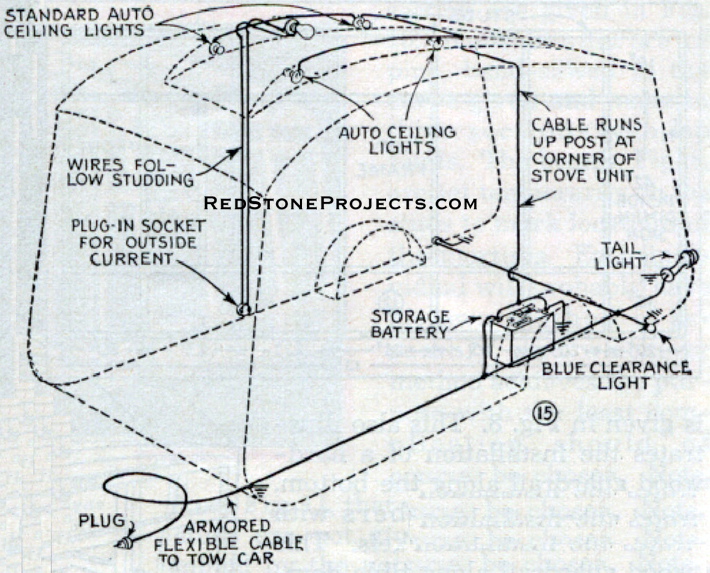

A wiring diagram, shown in Fig. 15, provides for a single

110-volt bulb supplied by outside current where this is available. The

outside current is led in through a plug-in socket mounted on the right

side of the trailer, on the underside of the guardrail. |

|

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

|

Figure 11.

Right Side Trailer Body Frame Detail

|

|

| Tail and clearance lights are connected to the towing

car through the usual plug and armored cable, and a storage battery placed

on the left side back of the fender takes care of four ceiling lights.

These are the standard automobile type with individual switches. The wires

from the storage battery are run up a post at a corner of the stove compartment,

and along a cross member of the roof to the lights on the other side. |

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures

and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

|

Figure 12.

Trailer Roof Cross Members

|

|

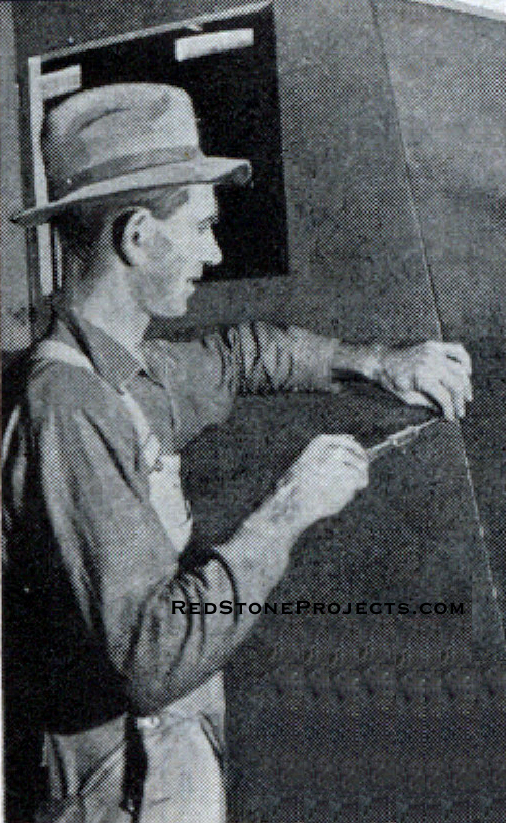

| For outside sheathing, 1/8-in. hard pressed board is

excellent material, having a very smooth finish and rigid structure. It

is obtainable in 4-ft. widths, and should be accurately marked by tacking

to the frame temporarily and outlining with a sharp pencil. Cut with a

sharp, fine-tooth saw and smooth the edges with No. 00 sandpaper.

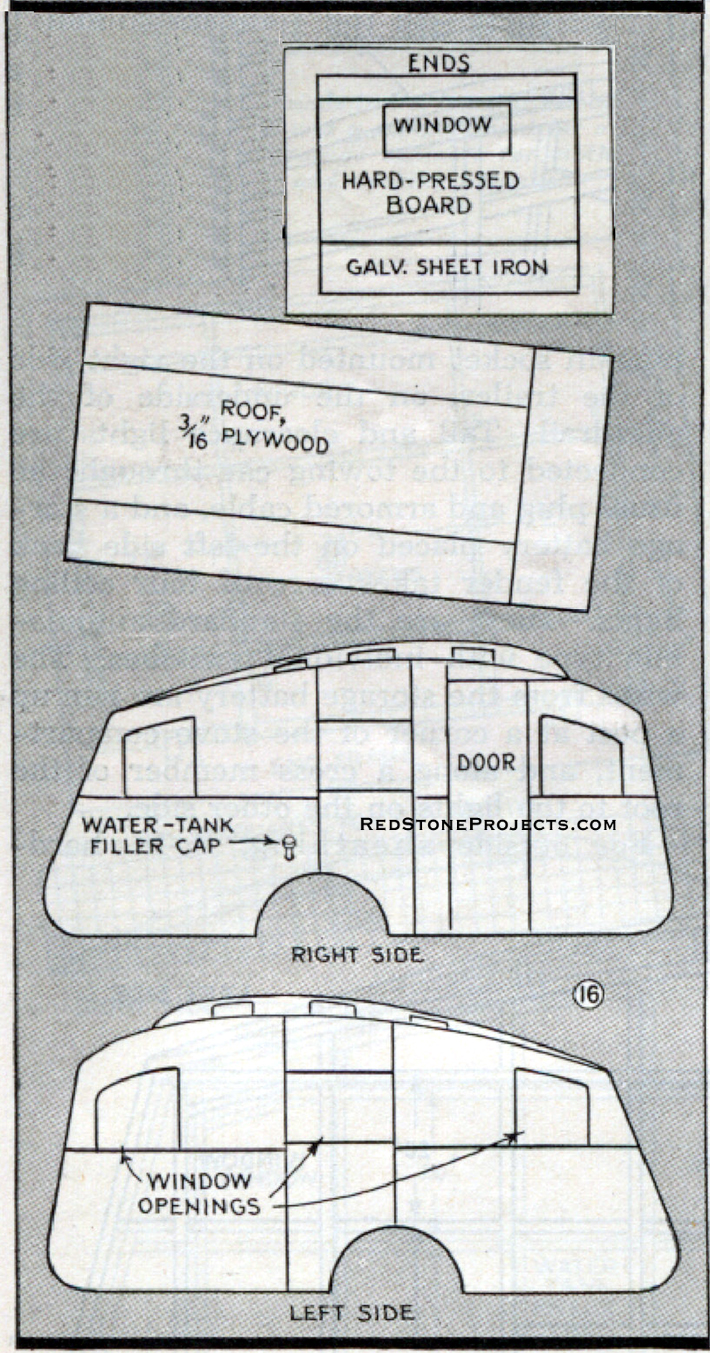

Fig. 16 shows when to join the sheathing. It is all installed

with flat-head, 3/4- in. brass screws, neatly countersunk. The joints of

the panels meet in the center of studs or other frame members, but around

windows and door frames the edges should come flush with the inside of

the frames. On the right side, before the panel is screwed on, the filler

cap and pipe for the water tank should be installed. If you wish to make

double walls, you can use the same material on the interior walls. Some

minor changes in the interior, such as position of cabinets and wiring,

will be necessary if you decide on double walls. |

|

|

Figure 13. Attaching the Trailer's Plywood Roof

|

| On the curved ends of the body, heavy galvanized-iron

sheets are installed, using flat-head brass screws. Hard pressed board

is used for the sides of the raised center section of the roof, but the

roof proper is entirely covered with 3/16-in. plywood, as in Figs. 13 and

16. This is later covered with a suitable roofing material. The plywood

is cut in four pieces, as in Fig. 16. |

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

|

Figure 14.

Left Side Trailer Body Frame Detail

|

|

| There are two ways of finishing the exterior. One is

to cover with Fabrikoid and the other to fill seams with plastic wood to

make an invisible joint, and spray the body with automobile lacquer or

enamel. Both finishes are very effective, especially when the lower half

is in a dark color to match the car and the upper portion, above the window

sills, in aluminum, with window sash to match the lower part of the body.

For that matter, any color that matches your car will give a pleasing contrast

with the aluminum-painted top. |

|

|

Figure 15. The electrical system adds materially

to your comfort. A storage battery supplies current for the auto-type ceiling

lights.

|

| Before the sheathing is put on, it is well to decide

on the interior finish. If you prefer all one tone, the painting can be

done anytime, on the interior. If, however, you like a light framing contrasted

with dark panels, paint the wood before the sheathing is set on. |

|

|

Attaching Trailer Sheathing

|

|

|

Figure 16. Trailer Body Sheathing

|

|

|

Selected as being representative of the type trailer

many of our readers have desired to see published in Popular Mechanics,

this trailer, of which this article is the third and last installment,

was designed and built by Mr. C. Hart Collins. We are indebted to him for

his kind cooperation in going through the entire construction in detail

so that complete information, based on the actual work, could be supplied

to our readers.

|

|

|

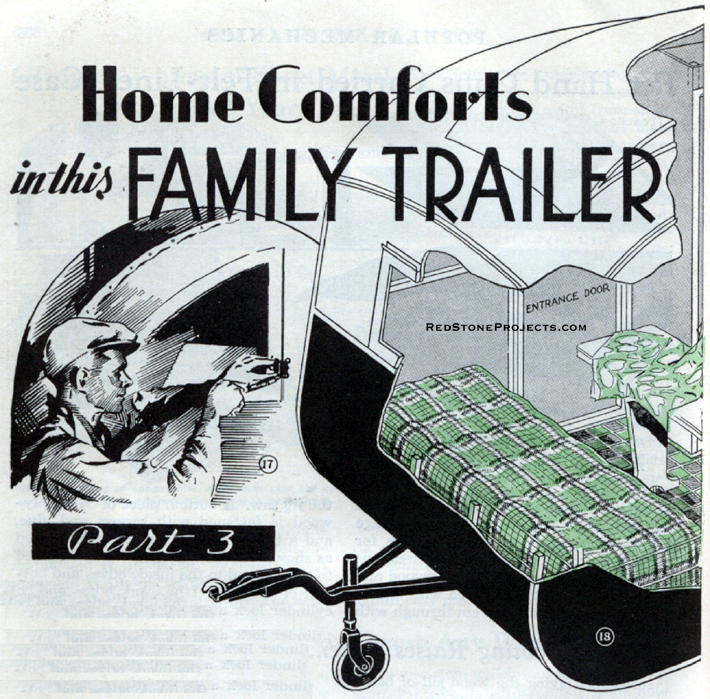

PART 3: TRAILER INTERIOR FURNISHINGS AND PAINTING

ONE glance at the cutaway view above and you have the

whole story of the interior furnishings. There's your kitchen, dining and

living room, and two bedrooms with clothes closet space. When you stop

along the road for the night, there's nothing to unpack, no ropes or awnings

to bother with. Simply uncouple the trailer from the car and park it in

any convenient place. One person handles it easily, even when fully loaded.

Now to finish the job. Remaining exterior details are

application of the roof of auto-top canvas and, if you have so decided,

a fabric covering of the body. In putting on the latter, you apply the

lower half of the wall covering first, then lap the upper half over it,

using copper tacks. A strip of auto-fabric binding is tacked over the seam.

Fig. 24 gives you the distribution of the material, and the sectional views,

Figs. 19 and 20, and the detail in Fig. 21 show what to do when finishing

up the top at the outer edge and around the ventilator openings in the

sides of the raised center section. Bindings of light aluminum angle are

used to finish all corners of the body as in Fig. 18. Where the top canvas

overlaps the sides it's a good idea to apply a light coating of marine

glue under the seam. Aluminum gutters around the edges of the top finish

this part of the job.

Window sash are made of white pine, rabbeted as illustrated

in Fig. 23, the corners joined with casein glue, dowels and corrugated

fasteners. The same figure shows how the copper screen is tacked to the

inside of the window frame. All windows swing outward on offset hinges

as in Figs. 17 and 18. Jointed brackets hold the windows in any position.

After you finish the exterior of the body you can permanently install the

A-frame and coupling and also the tail and clearance lights.

When you go inside, the first job is painting. An undercoating

and two applications of eggshell enamel in ivory or cream should take care

of this. Remember that you can easily make a double-walled job by sheathing

the interior walls and ceiling with pressed board or plywood. Now's the

time to do this if you desire. The interior walls and ceiling painted;

the next job is the floor. A linoleum covering, cemented down, adds to

the attractiveness of the interior and is easier to clean.

Now over to Figs. 25, 27 and 28 for the views and plan

of the stove, cupboard and sink. Fig. 25 shows a space-saving arrangement

of the drainboard. The latter slides down over the sink when not in use,

and the swinging arm which supports it when open folds back against the

cabinet.

The drain pipe from the sink is led down through the fender,

the end being bent so that the water does not strike the road wheel. The

cabinet which houses the cook stove is fitted with two drawers, a sliding

shelf, and a cupboard which houses the storage battery with additional

room for large utensils. There is more cupboard space above the stove.

A 3-in. vent, made as in Fig. 27, passes through this cupboard and the

roof to carry off cooking fumes.

In the main the framing for this cabinet can be the same

material as the body frame, 1 1/4 by 1 1/4-in. spruce. For panels you can

use pressed board or plywood. Doors, drawer fronts, and the sliding shelf

are best cut from 3/4-in. fir plywood. Fig. 28, with a plan and elevation,

shows you where to place the cabinet on the wall. Doors should have positive

catches so that. they do not swing open on the road. |

Figures

19, 20 and 21.

Here's what you have when the job is finished -a kitchen,

dining and living room, and two bedrooms with clothes closet space. Folding

studio couches make up into double beds. A three-burner stove, a sink with

running water and an icebox provides everything right at hand for getting

a meal. There's nothing to unpack when you stop.

|

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed On a Secure Server

|

| Drawers should have spring locks for the same reason.

You can buy a 25-lb. icebox which will fit in the position shown in Fig.

27, or one can be built in at about the same cost. The table, Figs. 22

and 27, is a simple folding affair made of either plywood or pressed board,

painted, of course, and is shown open in Fig. 22 and folded against the

wall in Fig. 27. Ordinary sliding door bolts are used to hold the table

in either position.

Installation of the clothes closet and the chemical toilet

as in Figs. 29 and 30 just about completes the job. The elevation, Fig.

29, will give you the size and position of these closets. For material

you can use either plywood or pressed board. It will save time to cut the

doors from 3/4-in. fir plywood for then there is no frame to make.

Notice that there is a flap hinged to the clothes closet

door. This flap hooks to the corner of the stove cabinet, the arrangement

forming a partition. All doors should have spring catches to hold them

closed. The chemical toilet is vented to the roof through the clothes closet

as in Fig. 29. There is a folding writing desk hinged to the back of the

clothes closet under a mirror. |

Figures

22, 23 and 24.

With the lower half of the body covered with waterproof

fabric, it is only necessary to paint the upper half in aluminum enamel.

If you omit the covering, then the sheathing is painted in the same color.

|

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed On a Secure Server

|

| A stool, which is really a box with a hinged top, does

duty both as a chair and added storage space. The top may be upholstered

as indicated. The beds are two studio couches, the end dimensions being

approximately those shown in Fig. 26.

Both can be made up into double beds. When folded there

is space in a lower compartment for the bedding. You will save time by

buying these readymade, as they are inexpensive. Fasten each to the floor

with bolts or screws.

Now you come to painting the cabinets, and, if you want

a first-class job, give the walls one more coat. If the doors have been

cut from 3/4- in. plywood, as is recommended, it will be necessary to fill

the edges of the plywood. |

Figures

25, 26,27 and 28.

Above you have the "kitchen" equipment, a stove, sink,

icebox and cabinet and also the dining table. At the right is a plan and

elevation showing where to build in the cabinet. The lower cupboard houses

the storage battery which furnishes current for the lights.

|

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed On a Secure Server

|

| A paste wood filler worked into the end grain on all

the exposed parts will build up a smooth surface for the paint. Work it

into the open grain with a cloth or your fingers, rub off the excess and

allow the filler to dry. Then sand the edges lightly with fine sandpaper

to level the filler and smooth up sharp corners. The trick in painting

cabinets of this sort is in covering all corners, edges, and the smaller

surfaces first, then finish off with the large areas. In this way you can

brush out the paint to a uniform coating much more effectively. To produce

a smooth, even final coat, it is necessary to be just as particular with

the primer as you are with succeeding applications. Another trick is keeping

the paint thinned to an easy brushing consistency to avoid a too heavy

application which cannot be brushed out to a thin film. This applies also

to the exterior paint job. |

Figures

29 and 30.

Generous clothes closet space and a compartment for

hats are provided for in the arrangement shown above. There's also a mirror

and a folding writing table. A flap on the clothes closet door hooks to

the stove cabinet and partitions the interior into two rooms.

|

Get a restored copy of these vintage 15 Foot Family

Vacation Trailer Plans with 40 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed On a Secure Server

|

| You should be particular with such details as the sliding

ventilator panels and the windows. The panels, Figs. 20 and 21, are best

removed while you are painting the slides, and the sash should be left

open until the paint is thoroughly dry. In this way you will avoid sticking

and possible breakage. The same thing is true of the closet and cupboard

doors and also the drawers. Now with the painting done, all that remains

is to fit and hinge the entrance door and provide a spring lock, and there

you are. |

Any 2 Vintage Trailer Plans

$19.95 FREE Shipping |

|

Select 2 Vintage Travel Trailer Plans

|

|

|