Free Shipping on All U.S. Orders

All Orders Processed on a Secure Server

Building Your Own Motor Caravan

Vintage Plans For a Light, Easy to Tow Camp Trailer

|

Building Your Own Motor Caravan

Vintage Plans For a Light, Easy to Tow Camp Trailer

|

PDF Format |

|

|

All Orders Processed

On a Secure Server

|

Price $12.95

|

|

Get a restored copy of these vintage Building Your

Own Motor Caravan Plans with 26 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

|

We will email these plans, to the address provided

with your payment, within 48 hours following receipt of your order.

|

|

|More

Vintage Trailer Plans|

|

|

|

|

|

|

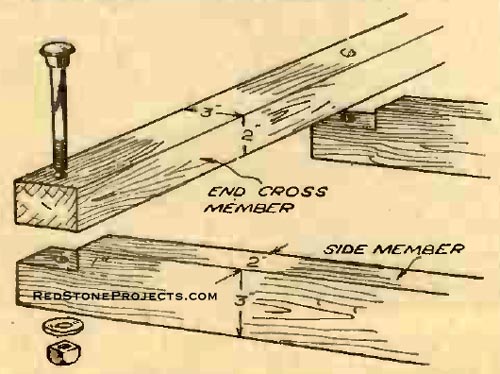

Building Your Own Motor Caravan

|

| HAVING enjoyed several very happy holidays in caravans

which had been hired on each occasion, it occurred to me early last year

that the building of a caravan of my own design would not be too difficult

a job, and would, in fact, be a somewhat intriguing way of spending leisure

moments and week-ends.

There were many points to be considered before making

a start, and the question of tools was first carefully reviewed, and it

was decided that my ordinary set - very ordinary - should meet the case,

this consisting of one household saw, one hacksaw, various chisels, spanners

and screw drivers, one small vice, one 4 -in. cramp, and all the usual

odds and ends that are accumulated by the average handyman. |

|

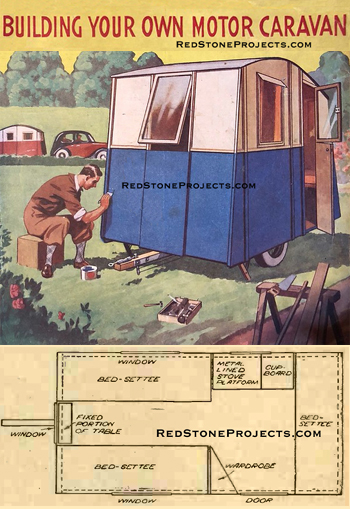

Constructional Details of an Attractive and Roadworthy

Three -Berth Caravan. It can Be Built for £20, and May Be Towed by

a

9-12 Horse-Power Car.

|

| Cost was naturally of considerable importance and on

rough figures it was estimated that the total should not amount to more

than about £20. Eventually it worked out a little less. Unfortunately,

there was no garage or storage place available, but the use of a large

tarpaulin seemed the only means of keeping the job clean and dry.

The Axle

The idea, after thinking over all the likely difficulties,

grew into realization and forthwith a suitable axle unit was selected from

a local car dismantler. There were so many different types and sizes of

axles to choose from that the first visit to the dismantler's was somewhat

bewildering. The points to consider were: (1) Extreme solidity; (2) Efficient

braking and easy brake operation; (3) Wheel base; (4) Spring base, that

is, distance between each spring; (5) Wheel and tire sizes.

Perhaps the spring base is of major importance, as in

view of the very considerable overall width of the caravan, the springs

should be mounted as wide apart as possible.

The average car front axle has a very narrow spring base,

apart from which there is always some difficulty in locking the swivels,

and as a scrap unit is probably in a worn condition the swivels would perhaps

be very slack.

This latter condition would naturally be very undesirable,

and for these last two reasons it was eventually decided to make use of

a rear axle assembly and one preferably with underslung springs.

The efficiency of the brakes on the average car rear axle

may, up to a point, be taken for granted, but large -diameter brake drums

are useful as the amount of effort at the brake lever is not very great.

With regard to wheel size, there is never very much choice, but an average

may be regarded as 19 in. with a low-pressure tire size 27 x 440 (or 450

x 19). |

|

|

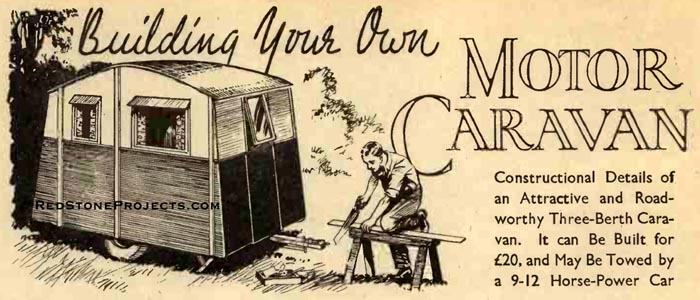

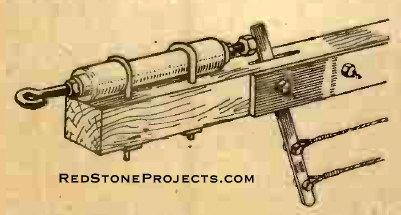

Figure. 1. Showing the hanger for the front end

of each spring, and the method of attaching the spring to the chassis.

|

| Axle Details

After a great deal of searching, I was fortunate in finding

an old Riley (which had been very badly damaged at the front of the chassis,

the rear axle, rear wheels and springs being apparently in quite sound

condition. The rear axle and springs seemed adequately to fulfill the requirements

under consideration, as the spring base was 37 in. center to center, wheel

track 4 ft. and spring camber 7 in. approximately. A few days later, when

the car was dismantled, I purchased the complete rear axle assembly, rear

wheels and springs, and then proceeded to make due alterations to adapt

the unit for use in the caravan chassis.

In doing this, the chief trouble lay in the fact of the

propeller shaft being enclosed by a long torque tube, but as the tube at

the forward end was already damaged, and in any case the propeller shaft,

bevel pinion and other parts were not required, I decided to cut the crown

gear housing short. On dismantling the differential and axle, it was found

that the brakes were in quite good condition, apart from the camshafts

being rather badly rusted, but it was not a difficult matter to put the

brakes in really very good order by cleaning and greasing the camshafts

and roughing up the brake linings.

The next step was the stripping of the differential assembly,

which was rebuilt with the crown wheel left out, only the differential

box and pinions remaining so as to provide a center bearing for both axle

shafts. The nose of the crown gear housing where it had been cut short

was blocked up with a plug of hard wood, and in finally fitting up the

cover plate a quantity of grease was put in the axle casing. The results

of this work were very gratifying, as the differential had an extremely

smooth movement, the braking seemed efficient, and the unit was undoubtedly

very solid.

Road Springs

For the time being I had to return to the work on the

axle unit, and took off the road springs for examination. Apart from being

somewhat rusty, they were quite sound and their camber seemed to be just

suitable to give clearance to a straight chassis side member. Some provision

had to be made for the axle unit to take the torque resistance when braking,

and as separate torque rod or member would only have involved extra weight

and unnecessary work, I decided to dowel the springs to the axle case,

using the existing spring dowel pins and letting down the spring platform

to grip the machined surface of the axle case. Apart from drilling the

axle case, which gave tremendous resistance to my comparatively crude tools,

there was no difficulty in doing this, although naturally great care had

to be taken in drilling the dowel positions at the exactly correct point

on the circumference of the axle case.

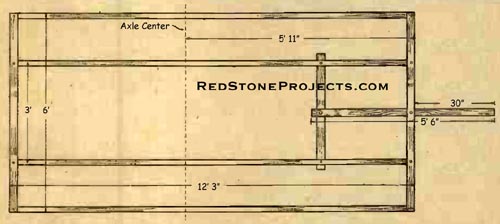

Making the Chassis

The undercarriage assembly having been completed, the

chassis members were prepared for fitting. The longitudinal members were

12 ft. 3 in. by 2 in. by 3 in. ash, cut to length and planed on each face,

and the cross members were also of 2 in. by 3 in. ash, 6 ft. long. Two

center longitudinal members were selected and were strengthened by bolting

to the 3 in. face, a strip of mild steel 1 1/2 in. by 3/16 in. for practically

the whole of their length. It was decided to mount the axle a little behind

center of the chassis in order to make the caravan slightly nose heavy,

and so add to its road -holding qualities. Accordingly, a point 9 in. behind

dead center of the center longitudinal members was duly marked, and the

axle offered up, thereby giving the location of the front shackle. This

was made by welding a strip of 1 1/2 in. by 3/16 in. mild steel to the

inside of an inverted spring shackle. (See Fig. 1.) |

|

|

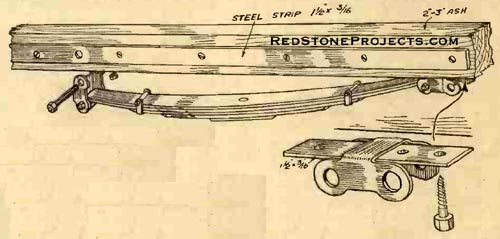

Figure. 2. Method of jointing used between the

ends of the chassis side members and cross members.

|

| The steel plate was drilled in three places and bolted

up to the underside of the chassis member. The rear end spring mounting

naturally had to be flexible and the spring suspended from a shackle in

a similar way to a motor - car front spring, and although the original

design incorporated the use of a car chassis shackle bracket, it was eventually

decided to bolt a 6 in. length of the strip steel previously used to the

opposite side of the chassis side member, drilling through the plating

on both sides, also the wood, to take a shackle pin carrying the top end

of the spring shackle. |

|

|

Figure 3. This is a plan view of the chassis frame

showing the principal dimensions.

|

| In determining the position of the top rear shackle bolt

the spring shackle was set vertically so that when the chassis was under

load there would be enough movement in a rearwards direction to provide

spring flexibility. A sketch of the spring suspension is shown in Fig.

1, both sides being identical. |

|

|

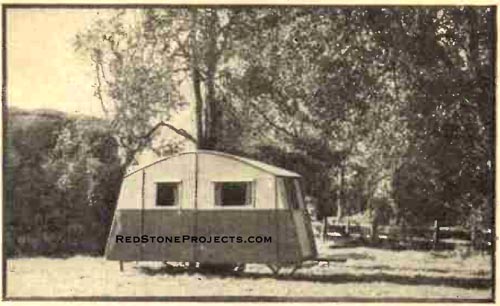

Figure 4. This illustration gives a good impression

of the appearance of the home-made caravan described.

|

To make up the total 6 ft. width of the chassis, two

extreme cross members were fitted back and front across the two already

assembled center members. The material used for these cross members was,

as before, 2 in. by 3 in. each, and the extremities of the center chassis

members were recessed 1 in., the cross members being carried on top of

the others and secured by 4 1/2 in. coach bolts (see Figs. 2 and 3). It

will be noted that the 3-in. face of the side member is vertical, whereas

the same face of the cross member is horizontal the extreme chassis side

members 12 ft. 3 in. and 2 in. by 3 in. each were then suspended from the

extremities of the cross members, being recessed in a similar manner to

the previous fitting. This arrangement gave all four chassis side members

an equal height, the fact being utilized when making and fitting the floor

boards, which was the next step. It would be as well to mention that before

covering the chassis, all the side members were heavily

creosoted and the undercarriage, springs and shackles well coated with

a good -quality paint. |

|

|

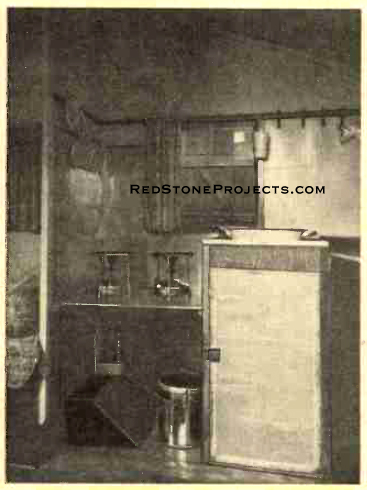

Figure. 5. A view of the inside of the rear compartment

showing cupboard and stove compartment.

|

| Fitting the Floor

The flooring was made of 7/16 in. tongued and grooved

weather boarding in 6 ft. lengths, each length being screwed down across

the top of each chassis side member. Special care was taken in fitting

the floor boards to strengthen the framework against twist or distortion

such as would be involved under normal road conditions. In the center of

the flooring the boards were reduced to 4 ft. width to clear the road wheels

which protruded above the height of the chassis members, leaving an aperture

30 in. by 24 in. on both sides to form a raised wheel arch which was built

later. Each length of boarding, before being finally laid down, was well

soaked in creosote, the top surface being left white so that the inside

color scheme could be decided upon later.

At a distance of 36 in. behind the extreme front cross

member and slung underneath the side members was bolted-up another cross

member to carry the back end of the trailer bar. For both trailer bar and

extra cross member, similar-sized timber was employed 2 in. by 3 in., and

the trailer bar before fitting was strengthened with a strip of 11/2 in.

wide steel bolted to its side. The trailer bar was attached to the front

of the chassis cross member by means of a 1/2 in. steel bolt with large

steel washers and a split-pinned nut, the rear end of the bar being similarly

treated.

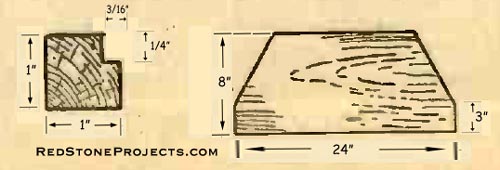

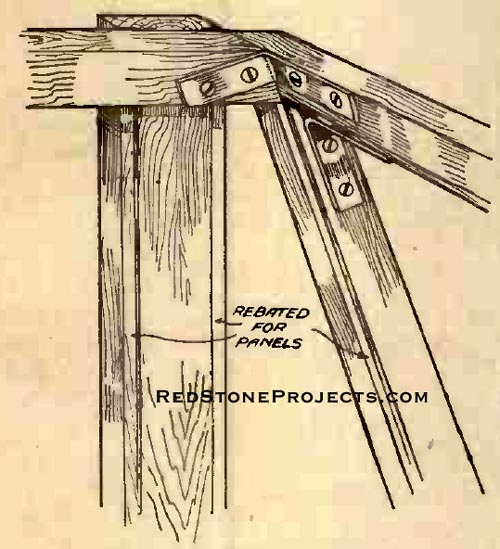

Bodywork

In view of the necessity for minimizing the total cost

of the caravan it was decided to make use of ordinary commercial 1/8 in.

plywood which is obtainable in a stock size of 5 ft. square sheets. The

timber for the body pillars was next ordered in 7 ft. lengths of 1 1/2

in. square, rebated 1/4 in. on one face, 1/8 in. deep (see Fig. 6) for

taking the end surface of each sheet of plywood. The two front side pillars

were, however, of a stronger material, 3 in. by 1 1/2 in., and similarly

rebated, the extra strength being considered necessary to take wind resistance

and other similar forces normally met under travelling conditions. |

|

|

Figure 6. Section of front pillars (left) and

of other body pillars (right).

|

| The front end was first assembled, and a triangular template

with an angle of 80 degrees was made so that the front corner pillars could

be set at the correct angle. The corner pillars (A) of 1 1/2 in. square

ash were cut to length, 5 ft. 2 in., and the front cross member recessed

so that when the pillar was screwed in position its angle conformed to

the template previously made. The front side pillars (B), of 3 in. by 1

1/2 in., were then fitted and bolted to the outside of the chassis side

members.

The space formed between the two pillars was filled up

with a sheet of plywood cut to shape, the bottom edge of the ply being

flush with the lower edge of the side member, and each contacting face

of the plywood glued, tacked and screwed.

A cross rail (C) of 1 1/2 in. square ash was then fitted

on top of the extremities of the front corner pillars, steel angle brackets

being the method of attachment in addition to the pillars and rail being

screwed together. (Fig. 7.) The center front pillars were recessed into

the front cross member similarly to the corner pillars and were again joined

to the roof cross rail by screwing and the fitting of corner brackets.

At a distance of 27 in. below the roof cross rail another cross rail (D)

was fitted between the two center pillars to form the aperture for the

front window and a plywood panel was cut and fitted between this cross

rail and the front cross member (on the outside face of the pillars) and

more plywood panels were cut and fitted to fill in the apertures between

the corner and center pillars, the plywood in this case being glued and

screwed to the inside face, thereby making a small bay of the center section.

(Fig. 8.)

Starting on the offside, the center pillar E, 6 ft. 8

in. in overall length, was bolted to the side member, and a complete sheet,

5 ft. square, of plywood fitted between its one edge and the front pillar

B.

The rear pillar F was similarly fitted, but its height

was not determined until the roof side rail had been sprung in position,

which necessarily had to be done very much later. The rear corner pillars

G, and center pillar H, were fitted on similar lines to the front pillars,

and the rear door post was fitted and left an indefinite length. The front

door post and nearside center pillar were erected and the spaces between

each pillar, excepting, of course, between the door posts, were filled

with sheets of plywood.

At this stage, the whole of the woodwork now assembled

was thoroughly primed with a red lead primer, particular care being taken

in sealing the edges of the plywood, the top edges having no support or

fixing as yet.

It was next necessary to secure the top extremities of

the front B and front corner pillars A by means of a specially-made corner

bracket (Fig. 10) and on the offside a rail (see Fig. 8) of 1-in. square

ash was fitted along the top edge of each plywood panel, extending from

the front corner pillar A to the rear corner pillar G, the rail being screwed

to the inside of each pillar and the plywood being glued, tacked and screwed

to the rail. On the nearside a similar rail was fitted, but terminating

at the front corner post, a short rail being used between the rear door

post A and the corner pillar G.

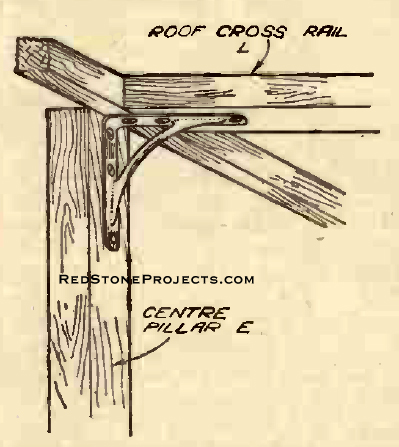

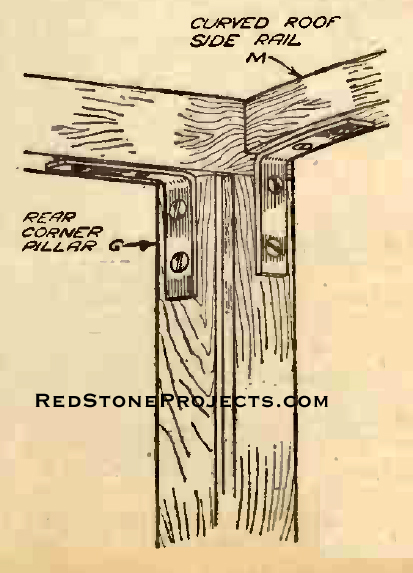

Curved Side Rail

The next step was to provide a pair of curved roof side

rails, and for this purpose two 12 ft. 6 in. lengths of 1 -in. square straight-grained

ash were obtained and, using the floor of the caravan, were bent on an

improvised jig and left for several days, occasionally being soaked with

hot water. After each day of this treatment the bend was gradually increased,

so that when the timber was eventually released its curvature corresponded

very closely to that required between the corner pillars A and G and center

pillars E. At the top of each center pillar a 3 in. by 3 in. reinforced

angle bracket was fitted as shown in Fig. 12. It was then a comparatively

simple matter to attach the one end of the curved roof rail to the top

of the rear corner pillar (Fig. 13) and then, after straining the side

rail over the center pillar brackets, screwing it directly to the top inside

face of the main front side pillars (Fig. 10).

This operation was repeated for the opposite side and

the center roof cross rail L was screwed on to the same brackets as the

side rails, after having been cut to such a length as to give a total width

of 5 ft. 9 in. between the two outside faces of the side rails. |

|

Figure 7. Elevation view showing the members constituting

the front of the body frame.

Figure 8. Nearside of the body framework.

|

Get a restored copy of these vintage Building Your

Own Motor Caravan Plans with 26 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

|

| Paneling

It was now possible to complete the paneling of the caravan

sides and accordingly the space between the curved roof rail M and the

lower side rail J was filled in with plywood sheets, the top edges of which

were cut to fit flush with the top of the curved rail M and, incidentally,

the center panel top bracket was removed and refitted to clamp the sheeting

between itself and the pillars. Although it would have been possible to

have covered the roof framework with the waterproof material already obtained,

it was thought that the inside finish would not be very satisfactory, apart

from the obvious difficulty of fitting the material smoothly, and so it

was decided first of all to cover the roof with plywood sheets similarly

to the body sides. As the overall width of the roof was 5 ft. 9 in., a

center rail had to be fitted through the length of the roof so that the

roofing could be made in separate panels. This rail was obtained as a 12

ft. 6 in. length of ash 2 in. by 1/2 in. and was quite easily fitted, its

curvature being almost identical with that of the side rails. The extremities

were screwed directly to the roof end cross rails, and the center roof

cross rail was recessed 1/4 in as an added steady, the joint of this being

glued and screwed. The roof behind the center pillars was covered in by

two separate sheets 5 ft. in length and approximately 2 ft. 10 in., and

as two more sheets of plywood cut similarly did not entirely cover in the

front end of the roof, an extra roof cross rail was made and fitted at

the point marked N in Figs. 8 and 11. The roof covering was then completed

by filling in the two comparatively small spaces at the front.

Waterproofing the Roof

After the outside roof paneling had been thoroughly dressed

with primer, it was covered with a single piece of waterproofed hood material,

similar to that used on cars, obtainable in 6 ft. widths and in several

different colors and shades. The color scheme decided upon was two shades

of green with cream uppers, and we were fortunate in obtaining a material

of a suitable shade of green. The material was merely stretched from end

to end of the roof and then drawn from side to side, and when finally,

it was perfectly smooth all over the roof it was tacked down. The lower

edges were left for the moment, as it was thought better to allow the weather

to take effect on the material before finally cutting off and fitting the

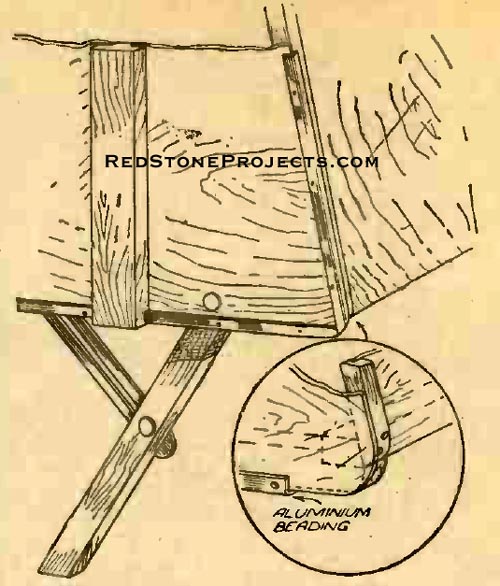

roof guttering. In order to protect the lower edge of each body panel,

angle strips of aluminum beading were fitted between the pillars and bedded

snugly against the plywood and the underside of the chassis side members,

a little putty being spread along the inside of the aluminum beading before

finally tapping down and pinning in position (see Fig. 15). This angle

beading was also used to protect the edges of the front window bay and

the edge of the plywood up each corner pillar.

The body shell being completed, the positioning of the

windows was decided upon and a window frame made for the front. For all

the windows planed deal 1 in. square rebated 1/4 in. by 3/8 in. (Fig. 16)

was used, the window frame corners being jointed in the orthodox manner.

The glass, after being cut to size, was bedded down into the window frame

with putty and secured by strip 1/4 in. round beading (Fig. 17). Similar

beading was also used as weather strip for the inside of the window aperture.

|

|

Figure 10. Method of joining the front corner

pillars.

|

Windows

Working from the inside of the caravan, the side windows

were marked out on the paneling, making a window aperture of 30 in. by

20 in. After cutting out this space with a hacksaw blade on an improvised

handle, a frame was built up around the inside, 1 in. square deal being

used and the window side pillars being jointed into the side rail. The

lower rail of the window frame was extended to the inside of the front

and center body pillars, making a waist rail above the seating position.

This rail P was screwed on to the pillars mentioned and was also pinned

and glued to the outside plywood.

A corresponding window was made to suit a similar operation

carried out on the opposite side. The offside rear window was made up on

identical lines, the aperture size being 20 in. by 20 in. On the outside

of each window aperture strips of lath wood were fitted to form a window

frame, and these strips were glued to the plywood and screwed through the

plywood into the window main framework, thus giving added strength and

also protecting the raw edges of the plywood where cut. In fitting these

outside strips, similar strips were used to finish the joints between the

lower sheets of body paneling and the top ones, and as a special precautionary

measure any slight space between the two sheets of plywood was filled in

with either red lead or putty before fixing, gluing and screwing the strips.

To improve the outside appearance and also help to keep the window hinges

watertight, louvres of sheet aluminum were made and fitted over each side

window. |

|

Figure 9. Rear body framework.

Figure 11. The offside of the body frame.

|

Get a restored copy of these vintage Building Your

Own Motor Caravan Plans with 26 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

|

| Outside Painting

All the outside paneling and pillars next received their

first coat of paint, and a line was drawn on each panel approximately 38

in. from the lower edge of the chassis side members in order to divide

the cream uppers from the green lowers. The door was made in two sections,

the top of the lower half coinciding with the color dividing line. Each

door section was built up of a separate frame covered on the outside with

a sheet of in. thick plywood, a Yale -type lock being fitted to the top

door, along the bottom inside edge of which was fitted an overlapping strip

to hold the lower door closed. Bolts were also fitted to the lower door.

The wheel arches were made up of boarding 10 ft. in width

and cut as shown in Fig. 16. These pieces were then screwed directly on

to the chassis side members in pairs, and a strip of sheet metal covered

the top of the wheel arch boards, being pinned into position and bedded

down into putty. The extremity of each strip of sheet metal terminated

underneath the floor boards, to which it was pinned and made watertight. |

|

|

Figure 12. Angle bracket used to fix the roof

cross rail.

|

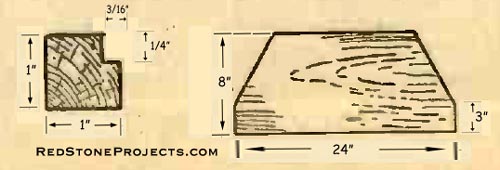

| Constructing the Beds

The framework of the beds was next built, using 1 in.

square deal and making as much use as possible of the already assembled

body pillars. The width of the beds was decided at 24 in., and the height

from the floor 16 in. It was thought that a concave base for the mattress

would improve the comfort and, accordingly, each bed top rail was planed

off on one edge to which the plywood was fitted as shown in Fig. 18. In

the 6 ft. length of the top bed rail three supports of 1 -in. square were

screwed to the underside and three similar struts were placed crosswise

between the two top bed rails.

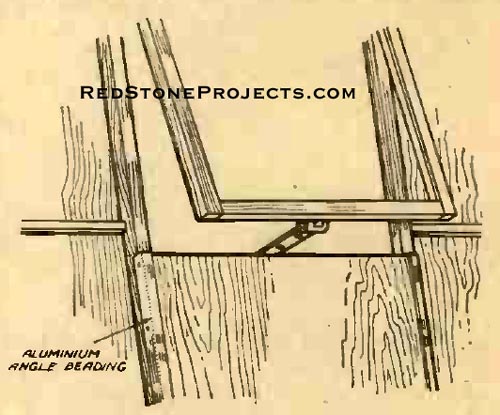

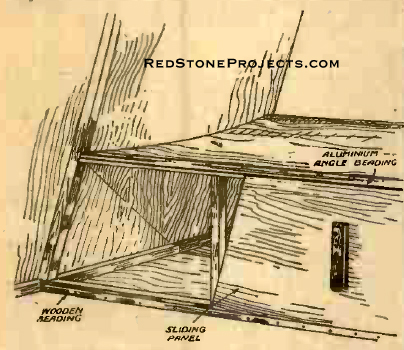

Plywood panels were then cut to fill in the 6 ft. length,

the edges of the plywood being glued and screwed as previously. One half

of the bed side had a fixed plywood panel, the front half being covered

in with a sliding portion, the slide rails consisting of a length of 1/4-in.

round beading screwed to the caravan floor, and a length of aluminum angle

bead screwed to the top rail. The rear bunk was built up on similar lines,

with the sliding panel on the nearside. |

|

|

Figure 13. How the curved roof rail is attached

to the corner pillar by means of an iron angle bracket.

|

| In making the center body partition the front bed corner

pillars were extended to the roof, meeting the center roof cross rail to

which they were joined and recessed. A dummy pillar 1/2 in. square was

screwed to the inside of the center body pillar and another cross rail

fitted between the partition pillars and the body side rail. The spaces

were then covered in with plywood panels extending right down to the wheel

arches. A cupboard 34 in. high and 18 in. by 18 in. was built in against

the offside wall almost underneath the window, and within a few inches

of the rear bunk. It had three shelves and the door was covered with perforated

zinc. A hole was cut in the top of the cupboard to accommodate a wash bowl

approximately 15 in. in diameter. |

|

|

Figure 14. The " Kitchen" showing the arrangement

of stoves and cup hangers.

|

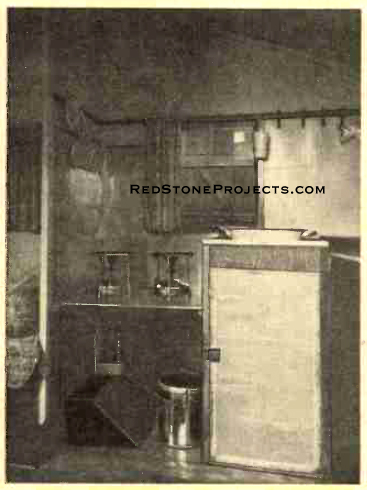

| The stove platform was made the same width as the cupboard

and fitted 24 in. above the floor boards, thus forming a recess between

the partition and the cupboard, the sides of which were lined with tinplate,

as also were the platform and caravan side panel. The object in doing this

was to prevent damage in case of a Primus stove catching fire. There was

ample room for two stoves, which, when travelling, were held down to the

platform by spring curtain wire with hooks and eyes. Below the stove platform

was room for carrying the paraffin tin and water container, which also

were secured with spring curtain wire hooked on to the side of the cupboard

and body. A built-in wardrobe was fitted across the nearside partition

pillar and the front door post, in triangular form, the door swinging towards

the caravan center and a mirror being fitted to the inside of the door. |

|

|

Figure 15. Fitting of the aluminum angle beading

and the rear body stay.

|

| Internal Painting

The whole of the inside next received its first and second

coats of cream paint and all the body side rails, roof cross rails, roof

center rail and window frames were picked out in green. It was decided

to have a folding table with the fixed portion 12 in. long screwed to the

underside of the front window cross rail, and strengthened by separate

angle pieces attached to the center front pillars. The folding portion

28 in. long and 20 in. wide, the same as the fixed portion, rested against

the same pillars when not in use and was held in position by a clip. When

the table is raised a folding leg is dropped on to a catch fitted to the

caravan floor. The floors and bunks were varnished stained and the table

taken down for French polishing. |

|

|

Figure 16. Section of timbers for window frame

(left), and shape of wheel arch panel (right).

|

| In the back compartment green linoleum was laid down,

and a strip of green -edged carpet was laid along the floor of the front

compartment.

A double flock mattress of 4 ft. width was obtained and

cut down the center, thus forming two separate mattresses 6 ft. long and

2 ft. wide, which just fitted the front bunks. As we were not carrying

a passenger, cushions only were used in the back bunk for the time being.

Soft Furnishings

The curtains and bed coverings were made of green folkweave

material, the mattresses having loose covers made with a small valance

hanging down in front. Spring-steel curtain wires were used for the curtains,

and owing to the angle of the front, it was necessary to use two such curtain

wires for top and bottom respectively. A hanging curtain of similar material

was hung across the partition, thus separating the two compartments. This

was kept folded back during the daytime. Several bright orange-covered

cushions decorated the caravan; the covers being taken off at night and

the cushions used as pillows. There was, of course, ample storage space

underneath the bunks for keeping the bed linen during the day.

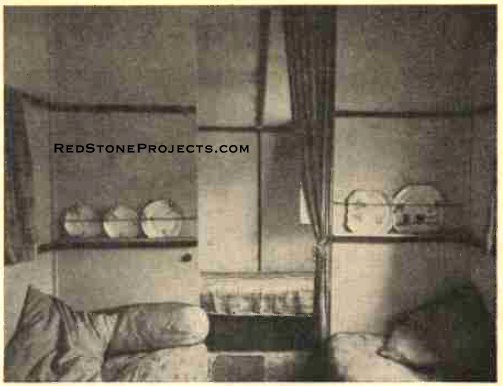

Along the body side rail in the rear compartment, ordinary

clothes pegs, painted green, were fitted about 2 in. apart for holding

the cups, and this method was found entirely satisfactory while travelling.

A frying pan and saucepan were hooked on to the kitchen side of the partition,

and on the front compartment side of the partition two 1 in. square rails

rebated 1/2 in. by 1/2 in. were fixed and painted green to carry a set

of gaily decorated plates, which, in addition, were secured by spring curtain

wire. (Fig. 20.) Spring curtain wire was also fitted inside the bottom

half of the cupboard to hold tinned goods in position when travelling. |

|

|

Figure 17. Hinged window at the rear of the body.

|

| Electric Light

An electric light for use from the car batteries was rigged

up with a lead through to the towing bar, and the light itself, with a

decorated shade, was hung from the middle of the center roof cross rail.

A small tumbler switch with green cover was fitted to the center partition

in a handy position just above the offside bunk. A small paraffin lamp

was also carried for use in an emergency and fitted in a clip underneath

the stove compartment.

A towel rail, obtained from a sixpenny stores, was fitted

to the lower door on the inside. The tail lamp and rear number plate were

carried on angle brackets immediately beneath the rear cross member and

suitably wired through to the tow bar.

Having thus completed the inside fittings and furnishings,

the outside of the coachwork received its second coat of paint, after which

aluminum water gutters were fitted round the sides and end of the roof

and the raw fabric edges cut off with a razor blade.

The parking jacks were then made, the design being quite

orthodox, consisting of a folding leg and adjustable stay as shown in Fig.

15. To finish off the dividing line between the green lowers and cream

uppers, strips of wood 1 in. by 3/16 in. were painted green and nailed

along the outside surface of the plywood panels. |

|

|

Figure 18. Details of one of the beds.

|

| Towing Bar

One of the last jobs was the fitting of a towing coupling

to the trailer bar. A very suitable connection was obtained from Messrs.

H. D. Trailers, Fieldgate Works, Kenilworth, for 17s. 6d., the coupling

consisting of a cylinder enclosing compression springs and a coupling rod

with a hook end for the actual connection to the car bracket. The cylinder

was secured to the tow bar by a pair of U bolts, holes for which were drilled

in the draw bar, and steel plates made and fixed underneath, thus clamping

the coupling and bar together (Fig. 19). The brake lever was fitted immediately

behind the coupling cylinder, a slot being cut in the trailer bar and a

mild steel lever 8 in. long pivoted to its center point on a bolt fitted

horizontally through the bar. The lower end of the brake lever was then

connected by cable to the brake camshaft levers in the axle unit, and cable

adjusters of the airplane type were fitted in tandem.

For maneuvering purposes, grip handles were screwed to

each corner pillar and these were found particularly useful when moving

the caravan from " dock." All is now ready for the first road test, and

it may be mentioned here that the caravan is so well balanced that in its

unloaded condition it can be balanced from the trailer bar on a fingertip,

although when travelling it is always advisable to load up the front compartment

to make it slightly nose heavy. |

|

|

Figure 19. The towing bar and automatic brake,

which is simple and effective.

|

| Final Tests

The first road test was gratifying, the braking and road

holding qualities being quite exceptional and certainly up to the standard

of various other caravans which I have previously handled. It seemed very

light and was very easily drawn by my 9-h.p. car. For anyone who knows

the district, it may be of interest to mention that the car and caravan

were taken up Peak Hill, Sidmouth, fully laden. This hill, I understand,

has in parts a gradient of 1 in 31.

Immediately following the short road test of about nine

miles, the caravan was taken on a tour round Devon, where it was eventually

parked for a few days at Sidmouth. Throughout the tour the caravan gave

no trouble whatever, and although a full kit of tools and spares were carried

there was no necessity whatever to make use of them. |

|

|

Figure 20. The inside of the" home on wheels,"

looking through the front window.

|

| Those who are skeptical about the use of plywood will

be interested to know that between September and the end of December the

caravan has been standing in an orchard exposed to all weathers and there

is no sign whatever of " lifting " or deterioration of the plywood, neither

have there been any leakages into the inside. |

|

|

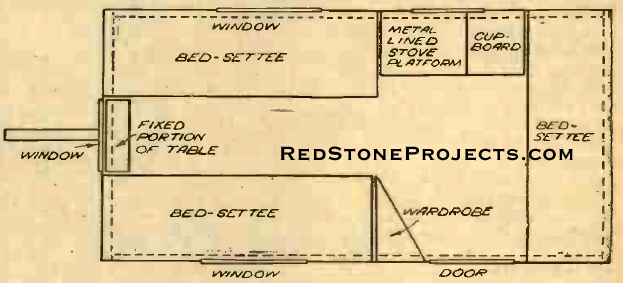

Figure 21. This plan shows the disposition of

the various fittings built into the caravan.

|

| A few words about the total cost may be of interest.

First, it should not be necessary to pay more than 30s. for an axle assembly

with springs, as most car dismantlers pay no more than £2 10s. for

a complete car. The supply of timber is best arranged from one source,

and a contract made as favorably as possible. This in particular applies

to the plywood, as it is very expensive unless purchased ix bulk. Most

of the inside fittings can be obtained from sixpenny stores, who can supply

all the window catches, cupboard hinges and locks and innumerable other

small parts of this kind. |

|

Any 2 Vintage Trailer Plans

$19.95 FREE Shipping |

|

Select 2 Vintage Travel Trailer Plans

|

|

|