Free Shipping

Build a Roof-Top Pop-Up Sleeper

DIY Hardside Car Top Camper Plans

|

Roof-Top Pop-Up

Sleeper Plans

Build this Car Top Mounted Hardside Pop-Up Camper

|

PDF Format |

|

|

All Orders Processed

On a Secure Server

|

Price $12.95

|

|

Get a restored copy of these vintage Hardside Car

Top Pop Up Sleeper Plans with 10 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

|

We will email these plans, to the address provided

with your payment, within 48 hours following receipt of your order.

|

|

|More

Vintage Trailer Plans|

|

|

|

|

|

WAGON-TOP SLEEPER

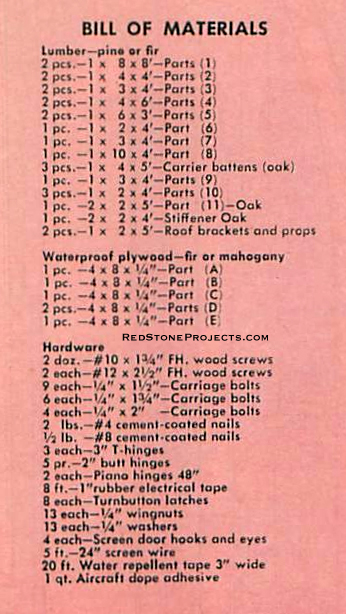

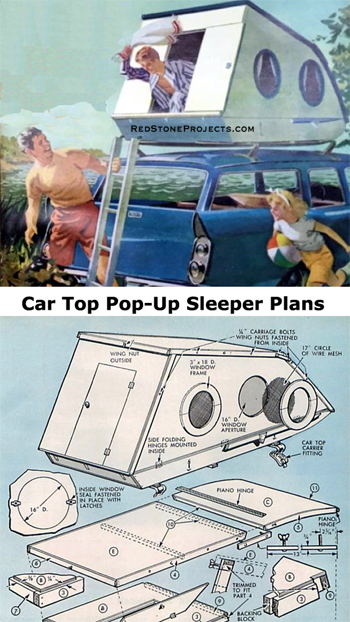

Bolted to a car-top carrier, this "upper berth" converts

any station wagon into a five-bed motel on wheels. Walls and roof interfold

flat for travel, and it sets up quick as a wink for those forty winks

By M. D. Shirley

|

| WITH THE KIDS bedded down in the wagon and mom and dad

tucked in "upstairs" on a soft inner-spring mattress, the "rugged outdoor

life" becomes a treat even a city softie can appreciate. With no ground

or roof top tent to set up, no bunking on the ground, no crawling things

to worry about - you're as snug as a bug in a rug, rain or shine.

Four screen-covered circular windows let you enjoy cool,

insect-free breezes on a sweltering night, and quick-fit window shutters

keep you cozy and dry during a storm. A removable pullman-type ladder,

which hooks over the wagon roof gutter, stows in the space between car

top and sleeper while you travel.

Folded, the unit resembles a flat-bottom boat only a foot

high, and because of its streamlined hull shape, you'll hardly know it's

up there while you're sailing down the highway. No tarp is needed to cover

it since interlapping, tape-sealed joints make the folded sleeper completely

watertight. |

|

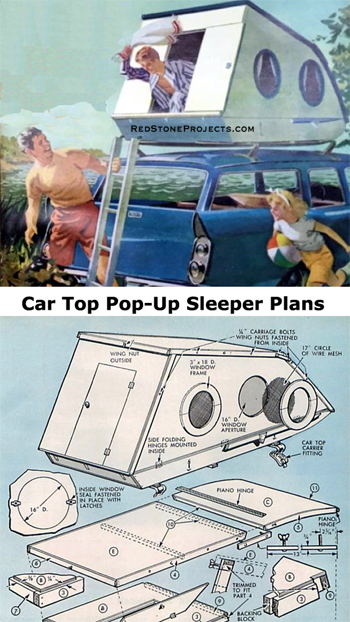

PROPPED UP ROOF and back panels of the sleeper

are locked together at angle on each side with wooden brackets tightened

on the inside with two wing nuts.

|

|

Erecting the sleeper is kids' play - just thirteen wing nuts

and you're in business. First the two screen-door hooks on each side (which

tie the roof down) are unhooked. Next the hinged filler strips on each

side are swung outward. The two-part top is raised at the center hinge

and propped up on each side with 13-in. lengths of 1 x 2 which are carried

separately for the purpose. These props hold the two sections at the angle

required for inserting the bolts of wooden tie plates in registering holes

in the roof sections. Wing nuts on the inside hold the tie plates. The

hinged top is now raised as a single unit and the front (door) wall is

swung up so a bolt may be inserted through its top frame member and the

forward flange of the roof, and secured with a fifth wing nut. Finally,

the sidewalls are swung up and fastened to the side flanges with four more

wing nuts on each side, making the thirteen.

In the folded position, the hinged sidewalls lay one on

top of the other, flat on the 48-in. mattress, the hinged front wall rests

on the sidewalls and the hinged top fits down over the whole thing like

the cover on a box. There's actually enough room inside to carry a second

mattress, as well as small camping gear.

|

THEN ROOF and back are raised as single unit and

front wall is swung up to support it. Single bolt through both sections

holds two secure with wing nut

|

|

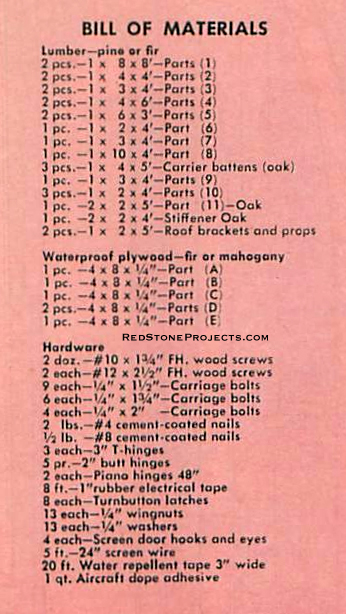

| First study the drawings to get a general idea of how

the parts hinge and fit together. Begin by laying out full-size patterns

of the curved rear ends of parts (1), (2) and (5). Note that part (2) rabbets

into part (5) and that part (1) rabbets into parts (2) and (5), so that

the solid lines of the pattern are not always the cutting lines. Both top

and bottom edges of these six piecesâ€â€Âas

well as parts (4) - must be rabbeted. Trace your pattern on 3/4-in. pine

or fir, positioning it to produce right and left-hand members, and saw

out. All rabbets are cut 1/4-in. deep (the thickness of the plywood) but

vary in width. |

|

LOOKING LIKE a boat hull when folded, all parts

pancake flat over mattress inside. Hull shape offers minimum wind resistance

when traveling on highway

|

|

Cut the rear-edge stiffener next from 1 5/8-in.square (2x2)

stock, 47 in. long, and install between the ends of parts (1) with two

#10 1 3/4-in. F.H. wood screws. This member also takes the screws for the

piano hinge that joins the top and floor sections, later on.

Cut part (8) from 3/4-in. pine and install between parts

(1) with three #10 1 3/4-in. FH. screws at each side. Note that the top

and bottom edges of this piece must first be beveled.

Ten saw kerfs 1/16 in. deep and 2 in. apart are made across

the rear end of panel (A) on the inside to facilitate bending the plywood

around the curved end of parts (1).

Turn the assembly upside down and nail the rear edge of

panel (A) to the 1 5/8-in. stiffener across the front, using #4 cement-coated

nails spaced 1 in. apart. Now dampen the inside surface of the plywood

by placing hot wet towels over the saw kerfs and gradually nail the panel

in the rabbets and across part (8), spacing the nails now 2 in. apart.

Trim off the panel flush with part (8).

Now cut three oak carrier battens 3/4 x 2 3/4 x 48 1/2

in. and attach each to the bottom edges of parts (1) with two #10 1 3/4-in.

FH. wood screws. Place one 30 in. from the back end and the other two 28

in. on centers. Three 1/4-in. holes are drilled through the bottom plywood

and the battens for 1/4 x 1 3/4-in. carriage bolts which are used to bolt

the sleeper securely to the car-top carrier brackets.

|

FINAL ERECTION step is swinging up sidewalls and

securing with four wing nuts on inside. Note hinged spacer strip that swings

outward at rear of sleeper

|

|

Make up the front wall and door by first cutting parts (3),

(7) and (9) from 3/4-in. stock. Note that part (7) is only 2 in. wide whereas

parts (3) are 2 3/8 in.; that parts (3) are chamfered at the lower corners

to assume the same angle as parts (1); and that, unlike the other side

members, parts (3) are rabbeted along the lower edge only. Nail parts (3)

to the ends of part (7) with #8 cc nails, then add plywood panel (B) after

cutting it 45 7/8 in. long and sawing out the 18 x 36-in. door. Use #4

cc nails for this, spacing them 2 in. apart. Note that the panel is recessed

from the outer faces of parts (3) and (7) to form rabbets as shown in the

detail on page 131.

Get a restored copy of these vintage Hardside Car

Top Pop Up Sleeper Plans with 10 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

Part (9) across the top of the front wall, measures 3/4 x

2 3/8 x 47 in. and has beveled top and bottom edges. This sets flush with

the edge of the panel - not recessed like the other framing members. It

fits between the 1/2 x 2-in. notches at the upper corners. To bridge the

gap between parts (3) and (9), a backing block is nailed to them both,

as shown in the details. Frame the door opening with 1 x 2s extending 1/2

in. into the opening to form a stop for the hinged panel. Three 3-in. T-hinges

are used to hinge the front to part (8).

Get a restored copy of these vintage Hardside Car

Top Pop Up Sleeper Plans with 10 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

Attach the hinged spacers next - parts (2) - securing each

with 2-in. butt hinges mounted on the outside. The sole function of these

parts is to fill the space behind parts (3) and make the sleeper watertight

when folded. Note here that the triangular blocks which fill the gaps that

open between folded parts (4) and (5), are backed up on the inside with

triangular pieces cut from scrap plywood.

Now the top assembly: Form the nose piece - part (11)

- from 1 5/8 x 2-in. pine to match your full-size section. Note that it

has a 1/4 x 3/4-in. rabbet cut across the top. Place parts (5) in position

on the assembly and drive a #12 2 1/2-in. FH. wood screw through part (11)

at each end, and into the end grain of parts (5). To prevent possible splitting

of the wood, drill pilot holes for these screws.

Now cut part (10) 3/4 x 1 1/2 x 47 in., bevel the top

and bottom edges as required and nail between the front ends of parts (5).

Again, make saw kerfs on the inside of panel (C), dampen with wet towels

as before and nail to part (11) first, then to the rabbets of parts (5).

Follow by adding a 48-in. long piano hinge to the front edge and make it

waterproof by placing a strip of rubber electrical tape between the hinge

and the plywood.

Assembly of the forward top panel presents no problems,

except that the top and bottom edges of part (6) and one of the parts (10)

must be beveled before they're nailed between parts (4); in addition, part

(6) must have a 1/4 x 1/2 in. rabbet cut in its beveled bottom edge. The

center brace (another 10) needs no bevels; it simply fits between the rabbets.

Now hinge the back wall and top together, placing rubber

tape under the hinge leaf as before. Holes for the tie-plate carriage bolts

are made through parts (4) and (5) on each side of the hinged joint. Finally,

this top-and-back assembly is joined to the bottom assembly with a piano

hinge across the joint between the stiffener and nose piece - part (11).

The two sidewalls, parts (D). are cut according to the

pattern. The cutouts from the circular windows are saved and used as bad-weather

shutters, secured with turn-buttons. Aluminum or plastic mesh is tacked

over the windows and the tacked edges are covered with overlapping circular

trim pieces. The sidewalls are hinged to the inside faces of parts (1),

mounting three pairs of butt hinges just below the top edges. The spacing

of the three notches in the top edges of the sidewalls, which must be made

to clear the roof crossmembers, are determined from the assembly itself,

after hinging.

Get a restored copy of these vintage Hardside Car

Top Pop Up Sleeper Plans with 10 Pages of Enhanced and Enlarged

Figures and Illustrations and Searchable Text.

All Orders Processed

On a Secure Server

|

|

| In order to make the sleeper completely watertight, glue

a strip of water-repellent cloth tape (3 in. wide) along the hinged joints

of parts (D) and (1) on the inside. With parts (B), (E) and (C) raised

and (D) collapsed, glue tape also at the forward corners between (1) and

(5), and at the aft corners between (1) and (3) on each side. The tape

at the corners fills voids which are necessary to permit (D) to fold. *** |

Any 2 Vintage Trailer Plans

$19.95 FREE Shipping |

|

Select 2 Vintage Travel Trailer Plans

|

|

|