|

||||||||||||||||||||||||||||||||||||||||||||

|

All Orders Processed on a Secure Server Build a Vintage 1937 Runlite Trailer Lightweight Traveling Bedroom and Kitchen Plans

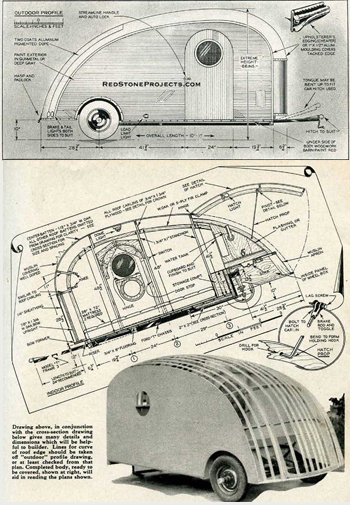

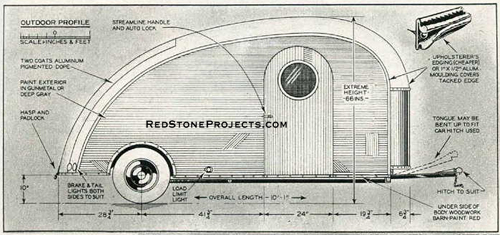

By placing the wheels quite far aft it has been possible to make this an underslung job, making it directly possible to combine really effective streamlining with marked stability. The weight of the whole trailer being so low, much of the weight is carried by the tongue, a matter of no particular concern in the case of the Runlite since it is normal for a load of 150 or even 200 pounds to be distributed on the hitch of all trailers. The Runlite can actually be towed at a 60 m.p.h. gait without straining any good light car. Straightforward methods of construction are used in this design.

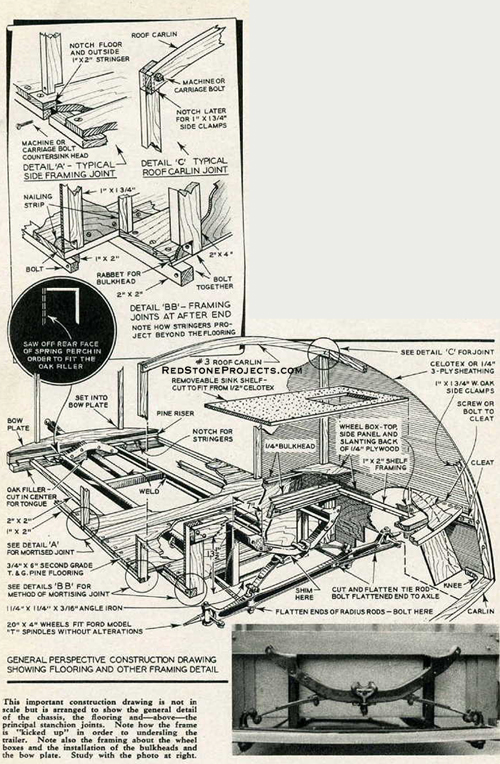

Another word before starting in on the actual construction work: Comparison will reveal some slight difference between photos and drawings in this article. It is quite unimportant and, as far as that goes, the curve, the width and the overall height may be modified to suit the builder's requirements. Start with the frame. What few welded joints you will have to make are encountered here. If you lack the proper equipment or experience have the welding data by on expert. The cost will be low and the sense of security a good deal greater. Use an old Model T Ford frame. At your local junk yard these should be anywhere from 75 cents to $2.75. Using a hacksaw, cut out a 13 1/2" length on each side 7" from the front end. Saw out the channels to fit and weld at right angles so that the frame now has a 13 1/2" kick-up as shown in the drawings. An angle iron tie piece 1 ¼"x 1 ¼" x 3/16" is welded across the bottom of the frame as shown in the perspective drawing of the frame. At the rear end the rear face of the spring perch is cut off with torch or hacksaw. Into the perch a 2"x 4", preferably of white oak, is carefully fitted. This beam should be the full width of the body and its obvious purpose is clearly shown in the drawings.

Only four leaves of the front spring are used. A shim is put under the perch clip bottom to compensate for the leaves removed. Second hand Model T steering tie rods are used in the manner shown for radius rods. The ball and socket fixtures for the frame end of the rods are from regular Ford radius rods. They should be welded on. The axle ends of the rods may be attached either by flattening and bolting direct to the wing spring perches, as shown, or drilled clear through the axle and bolted either side. This latter method provides an easy method of aligning the wheels. 20'x 4" wheels from a motorcycle pick-up trailer are used.

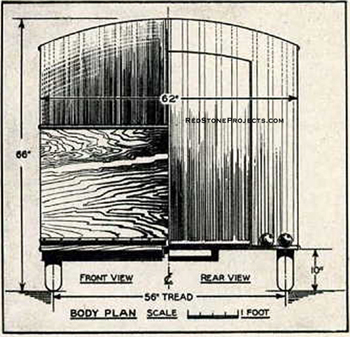

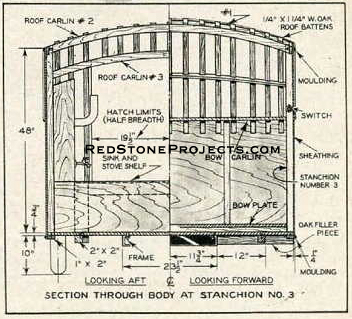

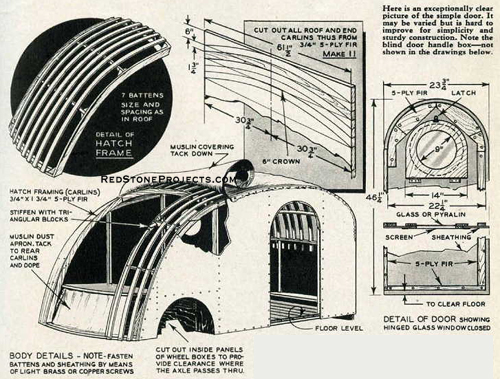

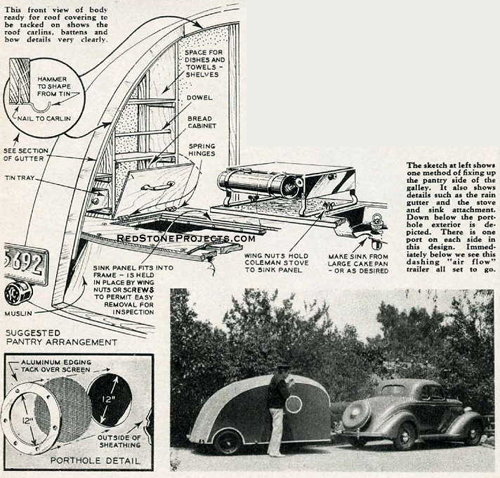

Build the floor as a foundation for the body. Second grade Oregon pine flooring, tongued and grooved, is bolted to the chassis frame starting at the rear end and working toward the towing end of the trailer. This flooring should be wide enough to finish 61 ½" wide after trimming the sides for straightness. Rabbet the first plank laid to hold the ¼" bulkhead as shown and cut out where necessary for the spring perch at the towing end. This cut out is later covered with tin - see drawings. Lay a straightedge along the sides and saw off flush. Next screw in the 1" x 2" and 2"x 2" stringers to the underside of the flooring as shown in the drawing, allowing the ends to project several inches beyond the floor at the rear. Stanchions No. 3 and the 2"x4" uprights are mortised into these projecting ends and the stringers trimmed off flush as shown in the detail sketches. The stanchion framing can now be completed. The heels of the stanchions are boxed into the floor and bolted into the 1"x 2" edge or side piece. With the main stanchions in the 1/4" plywood or hard Celotex bulkheads can be installed and the boxes for the wheels built up. Framing for cupboards, water tank, sink and so forth, is left until the body has been built. Cut out the crown carlins and also the bow plate. Detail drawings give the dimensions and it will be noted that it carlins in all are required. Some of these are used for the roof, three being bolted to the main stanchions already installed. The remaining carlins are required for bow and stern, and for the hatch. Install the bow plate in the manner shown. It is cut on a 72" radius, is 3/4" thick and 6 3/4" deep. It is screwed to the riser strip which in turn is bolted to the filler piece in the spring perch. The side clamps or roof strips can now be sawed to shape and mortised into the tops of the stanchions as shown. They may be lightly screwed until the outer sheathing is applied. This sheathing, of fir plywood, 1/4" thick, or hard Celotex, is screwed directly to the stanchions, floor edges and 1" x 2" outer strips. The carlins at the front and back of the trailer are put in with knees as shown. Do not apply the sheathing to the front end of the trailer until the roof battens have been bent in. If these prove stiff, soaking for half a day under the lawn sprinkler will render them pliable. They are fastened over the carlins without notches except where they bend into the front, or bow cabin. They are notched flush into this former. Use light screws to secure the roof battens. The lift-up cover over the galley, called a hatch in the drawings, is built up in the manner show. The longitudinal carlins are cut to the same sweep as the roof from 3/4" plywood. Cut out four of these carlins, two of them being permanently attached to the stern portion of the body frame as shown. The other two of course form the sides of the hatch itself. A tin gutter should be hammered out and fitted along the edges of the hatch opening in the manner shown.

The door is clearly indicated. Lock arrangement and so on is left to the DIY builder though a streamlined blind door handle was used on the trailer pictured. A 12" porthole is cut into the door and another one exactly opposite in the sheathing on the other side. A screen is secured to the outside of each port and inside they are furnished with hinged windows as clearly shown. Glass or airplane windshield Pyralin are equally satisfactory for these windows. It has been found that the two ports provide ample ventilation for even the hottest weather. The next step is to cover the roof. Use grade A muslin costing 18 to 29 cents a yard at most stores. Start at the front end, tucking on 1" centers with small carpet tacks, and stretch lightly over the sides as you proceed toward the rear until the tail carlin is reached. With two gallons of aluminum pigmented nitrate dope, you will be able to render the roof drum tight and waterproof. Correct procedure in doping cloth is to lay the first coat on around the edges and work toward the center. The edges can be finished with either aluminum edging or regular upholsterer's edging. Both are obtainable at automobile supply stores. The galley is pretty thoroughly covered in the various drawings. The space formed by the two bulkheads makes a good place for odd clothes or other stowage. It extends from wheel box to wheel box, is 18" deep and about 8" wide. Immediately aft of this compartment the sink and stove shelf is located.

The shelf rests on a light framing of 1" x 2" pine as shown in the drawings. It can be held in place by a few light screws or by four wingnuts.

A muslin apron, tacked from shelf carts to rear carlin and from wheel box inner panels, serves to keep the dust out. This apron should be doped. The tank for water may be any size and the details of its installation will naturally depend upon the size used. In any case, it should be so arranged as to empty directly into the sink. Cupboards and shelves may be any way you prefer. A simple arrangement as used by Mr. Trenmore Garstone, builder of the trailer illustrated, is shown in the sketches. Lighting details are left to the builder. Two dome lights proved ample for the mini Runlite.

Completed, your Runlite trailer should not cost more than $75.00 at the outside. It can be built for less if you know how and where to buy.

|