Free Shipping on All U.S. Orders

All Orders Processed on a Secure Server

Build a Shanty Boat

Vintage 21 Foot Houseboat Plans and Instructions

|

"Luxury" Shanty

Boat Plans

Build a Vintage 21 Foot

Budget Houseboat

|

PDF Format |

|

|

All Orders Processed

On a Secure Server

|

Price $12.95

|

|

Get a restored copy of these vintage Houseboat Plans

with 11 Pages of Enhanced and Enlarged Figures and Illustrations

and Searchable Text.

|

We will email these plans, to the address provided

with your payment, within 48 hours following receipt of your order.

|

|

| More Vintage

Boat Plans |

|

|

|

|

|

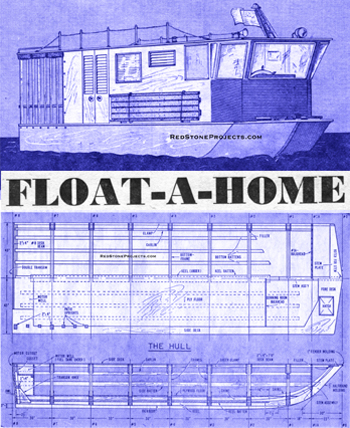

Figure 1. DIY Shanty Boat

|

|

| A HOUSEBOAT is a unique water craft in that it combines

most of the comforts of home with the mobility of a boat. Of course, use

is limited to sheltered waters, and speeds are slow in comparison to more

sea-worthy vessels.

Float-A-Home is a 21-footer that provides plenty of living

space for three or four persons. An extremely simple houseboat to build,

it features a strong hull with a heavy keel and close-spaced framing. This,

coupled with a relatively low profile, makes it a very stable craft.

Features include a conning room designed to provide an

unobstructed view forward and to the sides through glare-proof, swing-away

windows. The settee behind the helm extends to make a full length berth,

and in the main cabin, steps at the companionway can be removed to make

way for a fold-away berth. Of course, the entire interior arrangement can

be worked out to best suit your individual needs. Shown is an arrangement

where a section of the after deck is left open to provide a patio effect

on the starboard side, while the galley is to port. |

|

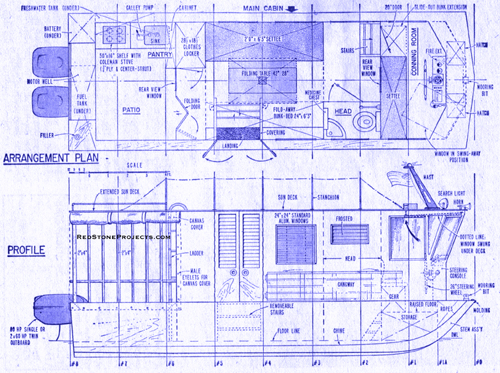

Figure 2. Shanty Boat Arrangement Plan and Profile

|

|

| Make up full-size patterns for the stem, transom knee,

and mast, as shown in Fig. 4, and for the stem plate as shown in Fig. 3.

Cut out these members from the proper stock as shown on the plans, and

assemble the stem. Fasten the two sections of the assembly with two 3/8-in.

x 6-in. #10 bolts, after countersinking for the bolt heads. Fasten the

stem plate to the stem with two 2-in. #10 flat head screws.

Make all measurements for framing directly on the wood

stock, and cut out the pieces. Cut out the transom panel and frame #1A

from 3/4-in. marine plywood. In all the following steps, be sure to coat

mating surfaces with marine resorcinol glue before final fastening with

screws, bolts, or nails.

Make up the transom as shown in Fig. 6, and the balance

of the frames as shown in Fig. 6 and Fig. 3. Use plywood gussets to reinforce

the frame corners. Notch all frames for keel, chines, and clamps, and notch

frames #1 and #1A for the stem assembly. |

|

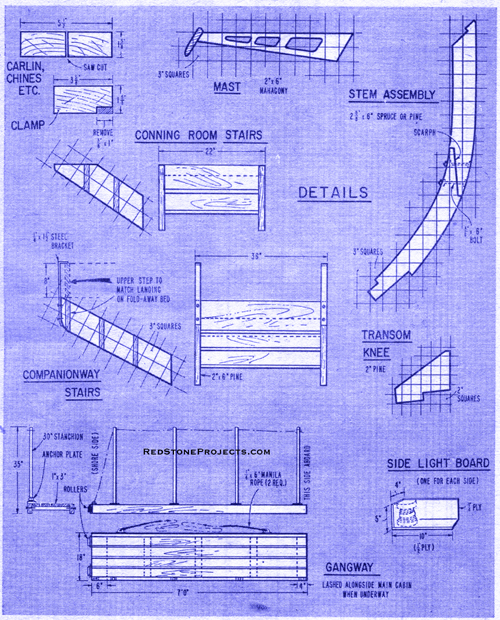

Figure

3. Shanty Boat Elevation and Plan View of the Hull

|

Get a restored copy of these vintage Houseboat Plans

with 11 Pages of Enhanced and Enlarged Figures and Illustrations

and Searchable Text.

All Orders Processed

On a Secure Server

|

|

| Line up the assembled frames, upside down, spaced as

shown in Fig. 3. They can be held in position by temporary 2 x 6-in. battens

nailed to each side. Attach the transom knee to the transom, and install

the stem assembly in its notches in frames #1 and # 1A.

Notch the keel for the transom knee, as shown in Fig.

6, and install the keel. It is fastened to the transom knee with two 3/8-in.

x 6-in. #10 bolts, and to each frame with a similar bolt long enough to

go through the keel and frame (and through keel, stem, and frame at #1).

Countersink for all bolt heads, and fill the holes with wood putty. It's

a good idea to cut a rabbet groove along each side of the keel at the fairbody

(the line where bottom paneling meets the keel) to take the edges of the

bottom panels. If this is not done, you should fiberglass this joint to

make it watertight and strong.

Next attach the clamps. These and the chines and carlins

are cut from lengths of 1 5/8-in. x 5 1/2-in. stock, as shown in Fig. 4.

Cut a notch along the bottom edge of each clamp, as shown. The top edge

of the plywood side panels will lie in this groove. In fastening the clamps,

start at the transom and work forward, alternating from one side of the

boat to the other at each frame. This helps to keep stress on the framework

even. |

|

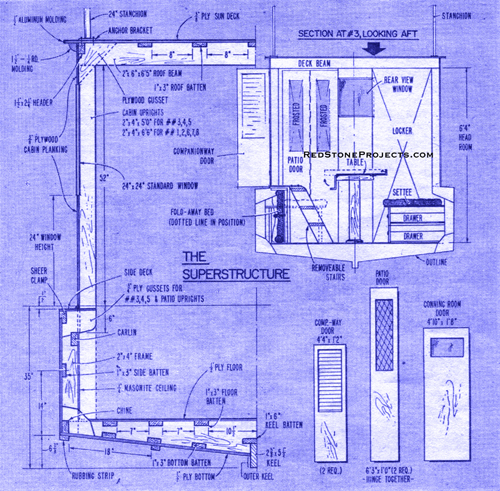

Figure 4. Shanty Boat Structual Member Details

and Dimensions

|

| Add the chines in the same manner; trim the ends of the

clamps and the chines so the chines will fit flush against the forward

ends of the clamps, and against the stem plate. Fasten clamps and chines

with two 1 1/4-in. #10 flat head screws at each joint. Now the temporary

side battens can be removed.

Tack bottom and side battens temporarily in place, and

mark all the frames for their notches. Remove the battens, cut out the

notches, and refasten the battens permanently with 2-in. #10 flat head

screw at each joint. Fair all framework so planking will lie flat.

Use lengths of builders paper to make templates for side

and bottom planking. It will be necessary to butt sections of plywood together

to make up the required length for each panel. All butt joints should be

backed along their entire length with 6-in. wide butt blocks of 3/4-in.

plywood. |

|

|

Figure 5. Shanty Boat Superstructure

|

|

| Install the side panels first, and trim the edges flush

with the chines. Use 1-in. #8 flat head screws, spaced about 2-in. apart,

and fasten to each frame as well as to transom, clamps, and chines. Install

the bottom panels in the same manner, trimming the edges flush with the

sides. Rubbing strips can be added, and fiberglassing can be done at this

time.

Give the finished hull at least three coats of a good

marine paint, and allow to dry thoroughly. Follow the paint manufacturer's

instructions carefully for best results. Turn the hull right side up, and

paint all interior surfaces that will be difficult, or impossible, to reach

after flooring, bulkheads, cabinets, and other joiner work is done.

Install the floor battens in the same manner as the bottom

battens were done. Install the carlins as shown in Fig. 3 and Fig. 5, and

finish off the hull interior with Masonite or 1/4-in. marine plywood ceilings

(interior side paneling). |

|

Figure

6. Shanty Boat Framing, Bulkhead and Transom

|

Get a restored copy of these vintage Houseboat Plans

with 11 Pages of Enhanced and Enlarged Figures and Illustrations

and Searchable Text.

All Orders Processed

On a Secure Server

|

|

| Make up the superstructure by installing the uprights

as in Fig. 5. Note that full-length uprights are at all frames except 3,

4, and 5, where the uprights reach just below side deck level. This allows

installation of berths that extend slightly under the side decks, giving

a little more floor room inside the cabin.

Install the roof beams across each pair of uprights, after

notching them for the headers. Install the headers in the same manner as

hull clamps and chines, then notch for the roof battens and install them.

Fasten cabin panels and the sun deck in place, with 1-in. #8 flat head

screws spaced about 2-in. apart, and add the finishing trim and molding

after the narrow side decks and fore deck have been fitted. |

|

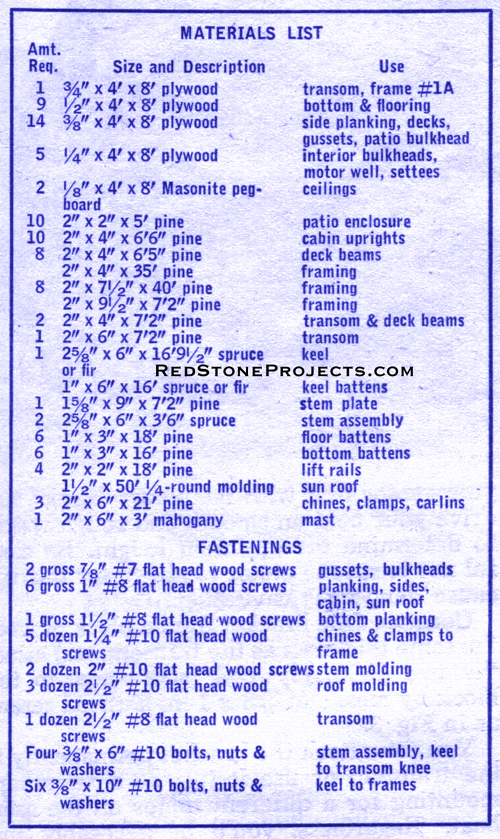

Shanty Boat Materials List

|

| Windows, doors, and other finishing touches can be added

as shown in the plans, or the entire superstructure can be modified to

suit your individual ideas and the availability of door and window units

in your area. Make up the motor well as indicated in Fig. 2 and Fig. 3,

and a steering console of your own design. Install mast, lights, cabin

fittings, and all hardware and furnishings.

Mount a single motor or two motors totalling no more than

120 horsepower on the transom, and you're ready for the water. *** |

FLOAT-A-HOME SPECIFICATIONS

Length 21 Feet

Beam 7 Feet 3 Inches

Power 120 hp. Maximum

Cost $850 approx. |

|

|